The Art of Invisibility: A Designer's Guide to Seamless Textures

By Mira Kapoor | 10 September 2025 | 13 mins read

Table of contents

Table of Contents

Ever see a digital fabric mockup and just know it's fake? There's often a small, repeating flaw or an obvious seam that shatters the whole illusion, making stakeholders hesitant to leave traditional workflows behind. This is where understanding the seamless texture becomes your strategic advantage. We’re going to unpack what a seamless texture really is, not just as a technical file, but as the foundational principle for building a faster, more convincing, and cost-effective design pipeline. Think of this as the shared language between a 3D render and a physical bolt of fabric; getting it right is the first step to connecting your digital vision to production reality for good.

What is a seamless texture, really?

Before you can master seamless textures, you need to truly understand what they are and what they aren’t. While the term gets tossed around a lot in design circles, its real value lies far beyond being just another technical file format. A seamless texture is the foundation of creating believable, high-quality visuals. It’s what allows a digital material to look infinite, natural, and unbroken no harsh edges, no distracting seams. Getting this right is the first step toward producing digital assets that look as real as the physical fabrics they represent.

Beyond the buzzword: Defining surface continuity

The term seamless texture gets thrown around a lot, often losing its meaning. At its core, it’s not a buzzword; it’s a foundational principle for any designer working with surfaces, whether on a screen or a bolt of fabric.

So, what makes a texture seamless? It’s the ability for an image or pattern to be tiled, placed side-by-side with itself, without any visible seams, edges, or interruptions. Think of it like high-end wallpaper. When it’s done right, you can’t tell where one sheet ends and the next begins. The pattern flows with perfect surface continuity, creating the illusion of a single, unbroken material. When it’s done wrong, you see the grid. The illusion shatters.

This matters for two critical reasons. In digital mockups, a visible seam on a 3D garment instantly screams “fake.” It breaks the immersion and cheapens the design, forcing clients to focus on the technical flaw instead of the creative vision. In the physical world, this concept is even older. For centuries, textile pattern design has been built on creating repeats that flow perfectly across a roll of fabric. A poorly designed repeat leads to wasted material, awkward pattern breaks on the final garment, and costly production errors. Whether you’re rendering a virtual prototype or printing a thousand yards of silk, the goal is the same: to create a believable, continuous surface that supports the design, not distracts from it.

The key characteristics of high-quality seamless textures

A truly effective seamless texture is built on more than just invisible edges. It’s a careful balance of three key characteristics: resolution, repetition, and realism. Nailing these is what separates professional-grade assets from amateur attempts.

- Resolution: This is all about clarity and detail. A high-resolution texture looks sharp even when viewed up close. If you’re designing a virtual tweed jacket, you want to see the individual fibers and nuances of the weave, not a blurry, pixelated mess. Low resolution is a dead giveaway that you’re looking at a digital shortcut. The rule is simple: start with the highest quality source image possible. You can always scale down, but you can’t invent detail that was never there.

- Repetition: This is the subtle art within the science. A texture can be technically seamless but still fail if the pattern is too obvious. If a unique knot in a wood grain or a prominent floral motif repeats every few inches, the human eye will spot the pattern instantly. This is often called the tiling effect, and it’s just as distracting as a visible seam. The best seamless textures feel random and organic, even though they are based on a repeating tile. This is achieved by avoiding overly distinct features or by using larger texture maps that make the repeat less frequent.

- Realism: This goes beyond the pattern itself and into how the material interacts with light. A high-quality texture includes corresponding maps like normal, roughness, and ambient occlusion maps that tell a 3D engine how the surface should behave. Does it absorb light like matte cotton or reflect it like polished leather? Does it have physical depth, like the grooves in corduroy? Without these, even the best pattern will look flat and lifeless. Realism is what makes your digital fabric feel tangible.

Consider the difference. A bad seamless texture might be a low-resolution photo of denim where you can see the same distinctive frayed thread every two inches. A good seamless texture is a high-resolution map of that same denim, but the repeat is so well-hidden and the lighting information so accurate that you could zoom in and almost feel the fabric's tooth. Understanding this distinction is the first step toward building a more efficient and believable design pipeline.

Bridging two worlds: Fabric vs. Digital applications

Seamless textures aren’t just a digital design concept; they’re deeply rooted in centuries-old textile practices. Whether you’re printing fabric for a real-world collection or applying textures to a 3D garment, the goal is identical: create a continuous, uninterrupted surface. This section explores how seamless principles connect these two worlds, revealing the shared challenges and techniques that unify fashion design and digital visualization.

Understanding seamless texture in fabric and digital design

At first glance, designing a digital fabric for a video game and creating a pattern for a real-world fashion line might seem like entirely different disciplines. But dig a little deeper, and you’ll find they’re both solving the exact same problem: how to apply a finite pattern to an infinite or complex surface without it looking broken. The core principle of the seamless repeat is the universal language they both speak.

For fabric, the challenge is physical. A roll of printed textile can be hundreds of yards long. The design must repeat flawlessly, both horizontally and vertically, to ensure that no matter how the fabric is cut and sewn, the pattern remains consistent. This is the foundation of fabric texture techniques that have been refined for centuries.

In digital texture creation, the challenge is virtual but no less complex. Instead of a flat roll of fabric, you have a three-dimensional model with curves, folds, and corners. The goal is to wrap this 3D object with a 2D image texture so perfectly that it looks like the object was made from that material. The challenges are different; one deals with industrial printing presses, the other with UV coordinates and rendering engines, but the underlying need for a seamless, continuous pattern is identical.

In the digital realm: Texture mapping for design visualization

If you’ve ever seen a 3D model with stretched, pinched, or broken patterns, you’ve witnessed bad texture mapping. Texture mapping is the process of projecting a 2D image onto a 3D surface. A seamless texture is the most critical ingredient for making this process work.

When a 3D artist creates a garment, they unwrap its virtual surface into a flat, 2D pattern, much like a real-world sewing pattern. This 2D layout is called a UV map. The seamless texture is then applied to this map. If the texture isn’t seamless, you’ll see harsh, ugly lines wherever the edges of that UV pattern meet on the 3D model along a sleeve seam, at the waist, or across the shoulders. A high-quality seamless texture ensures that when the software tiles the image across this surface, the transition is invisible. This is how you create believable virtual prototypes that allow you to assess a design’s drape, fit, and finish long before a single thread is sewn.

In the physical world: Fabric texture techniques and production

Long before 3D models and rendering engines, textile designers were mastering the art of the seamless repeat. In textile pattern design, the goal is to create a block or tile that connects to itself perfectly on all four sides. This block is then used for screen printing, roller printing, or programming a loom for weaving.

Here, the stakes are tangible. A flaw in the seamless design doesn’t just mean a bad render; it means thousands of dollars of wasted fabric. The repeat must account for the physical constraints of the printing machinery and the way the fabric will be used. For example, a large, obvious repeat might be fine for upholstery but disastrous for a tailored dress where pattern matching is key. By designing seamlessly from the start, you create a direct link between the digital drawing board and the factory floor. A file approved in a design tool can be sent directly to a manufacturer, confident that the resulting fabric will match the digital vision, ensuring surface continuity and minimizing costly miscommunications.

The workflow: How seamless textures are made and used

Understanding seamless textures is one thing, but integrating them into your design pipeline is where the real magic happens. From sourcing materials and generating texture maps to applying them in 3D prototypes and handing off files for production, each step relies on precision and consistency. Here, we’ll break down the workflow that transforms a simple fabric swatch into a powerful asset that drives your entire design process from concept to creation.

An overview of digital texture creation methods

Knowing you need a seamless texture is one thing; creating one is another. The good news is that the tools for digital texture creation have evolved significantly, moving from painstaking manual processes to intelligent, automated workflows. Understanding the options is key to finding a method that fits your team’s skills and needs.

Historically, the go-to method was Photoshop’s Offset Filter. This tool essentially shifts your image horizontally and vertically, moving the edges to the center. This reveals the seams, which you would then manually clone, paint, or patch to blend them away. It’s effective, but it’s an art form that requires time, patience, and a good eye. For complex, organic textures, it can be a significant bottleneck.

Today, modern tools have streamlined this dramatically. AI-powered generators and specialized software can analyze an image and produce a perfectly seamless version in seconds. These tools are incredibly powerful for a few reasons:

- They understand context. Instead of just blending pixels, they can generate new, plausible texture information to fill in the gaps, making the result feel more natural.

- They save enormous amounts of time. A task that took a skilled artist an hour can now be done in under a minute.

- They democratize the skill. A designer without deep digital painting experience can now create high-quality seamless assets, freeing them to focus on the creative aspects of texture design.

To get the best results, start with a flat, evenly lit photograph of a material. Avoid strong shadows or highlights, as these will create noticeable repetition when tiled. The goal is a neutral base that can be lit realistically later in a 3D environment.

Applying seamless textures in a fashion design pipeline

A seamless texture isn’t just a file; it’s a vital asset that moves through the entire design pipeline. Integrating it effectively can eliminate friction between the creative and production stages.

Here’s what that looks like in practice:

- Initial design & sourcing: The process begins with sourcing a material concept. A designer might photograph a unique fabric swatch or use a digital material library. This source image is then made seamless using one of the methods described above.

- 3D prototyping: The seamless texture is applied to a 3D model of the garment. This is the first reality check. Here, you can evaluate the scale of the pattern, how it behaves across seams, and how it drapes on the body. Because the texture is seamless, you get a clean, accurate visualization without distracting technical glitches.

- Virtual approvals: This digital twin of the garment is shared with stakeholders for review. Instead of interpreting a flat sketch, decision-makers can see a photorealistic render of the final product. This accelerates approvals and ensures everyone is aligned on the vision.

- Production handoff: Once the digital sample is approved, the seamless texture file becomes the master reference for production. It can be sent directly to a textile mill for printing, with exact specifications for color and scale. This direct digital-to-physical link reduces the risk of errors and misinterpretation that often occur with physical handoffs.

By adopting a seamless approach from the outset, you’re not just making prettier renders. You’re building a more coherent, efficient, and error-resistant workflow from concept to collection.

The strategic advantage: Why this matters for your team

Seamless textures aren’t just a technical improvement; they’re a business advantage. By adopting a seamless-first approach, your team gains speed, reduces costs, and builds a tighter connection between digital design and physical production. In this section, we’ll dive into the tangible ROI of integrating seamless textures into your pipeline and how it positions your team to stay competitive in an increasingly digital-first fashion landscape.

Justifying the ROI: Efficiency gains from a seamless workflow

Adopting new tools and workflows often comes down to one question: what’s the return on investment? For a seamless texture pipeline, the ROI isn’t just clear, it’s compounding. It’s about saving time, cutting costs, and making smarter creative decisions.

Think about the hidden costs of a traditional, disconnected workflow. How many hours are spent manually fixing tiling errors in a 3D render? How many days are lost waiting for a physical sample to arrive, only to find the pattern scale is wrong? These inefficiencies add up.

A seamless workflow attacks these problems directly:

- Reduced rework: High-quality seamless assets work correctly the first time. This means less time for your 3D artists spent troubleshooting UV seams and more time on creative lighting and styling. It’s the difference between fighting your tools and using them to elevate your work.

- Faster approvals: Photorealistic virtual prototypes built on seamless textures leave less room for ambiguity. What you see is what you’ll get. This clarity allows for faster, more confident decision-making, shrinking the overall design cycle from weeks to days.

- Lower sampling costs: Each physical sample costs money in materials, in shipping, and in time. By perfecting the design in a digital space, you can drastically reduce the number of physical iterations needed. Getting it right on screen means you only need to produce what you intend to sell.

Ultimately, a seamless workflow improves communication. When the digital asset used for design visualization is the exact same file used for production, you create a single source of truth. This aligns your design, marketing, and manufacturing teams around a unified vision, reducing errors and ensuring brand consistency.

The Future: Integrating seamless texture design into your innovation strategy

Mastering the concept of the seamless texture is more than just a technical skill; it’s a strategic imperative. In an industry moving rapidly toward digitalization, the teams that can fluidly bridge the gap between digital design and physical production will have a decisive competitive edge.

By building this competency, you empower your team to leverage 3D tools to their full potential. You’re not just dabbling in 3D; you’re building an end-to-end digital pipeline. This doesn't just make you faster; it makes you more agile. Want to test a new colorway? It’s a 10-minute task, not a two-week wait for a sample. Need to create marketing materials before the first garment is even produced? You have a photorealistic digital twin ready to go.

Positioning your team as a leader in digital-to-physical fashion creation starts with mastering these fundamentals. Understanding how to create seamless textures for design isn't just about making better pixels; it’s about building a smarter, more resilient, and more innovative business. It’s the engine for turning creative ideas into commercial reality, faster and more effectively than ever before.

From principle to pipeline

So, what is a seamless texture at the end of the day? It’s not just a technical file; it’s the common language between your digital vision and your physical product. It’s the asset that ensures what you design on-screen is what you get from the mill, without costly surprises.

Mastering this principle means you’re no longer just making digital mockups; you’re building a smarter, more resilient pipeline. You’re cutting down on physical sample costs, speeding up approvals, and giving your team the confidence to trust their digital tools. You’re turning a potential technical headache into a genuine strategic advantage.

Think of it this way: the most expensive seam isn’t on the texture. It’s in the workflow that the disconnect between a great idea and a finished product. By making seamless your standard, you’re not just fixing the image. You’re fixing the process.

Mira Kapoor

Mira leads marketing at Texturly, combining creative intuition with data-savvy strategy. With a background in design and a decade of experience shaping stories for creative tech brands, Mira brings the perfect blend of strategy and soul to every campaign. She believes great marketing isn’t about selling—it’s about sparking curiosity and building community.

Latest Blogs

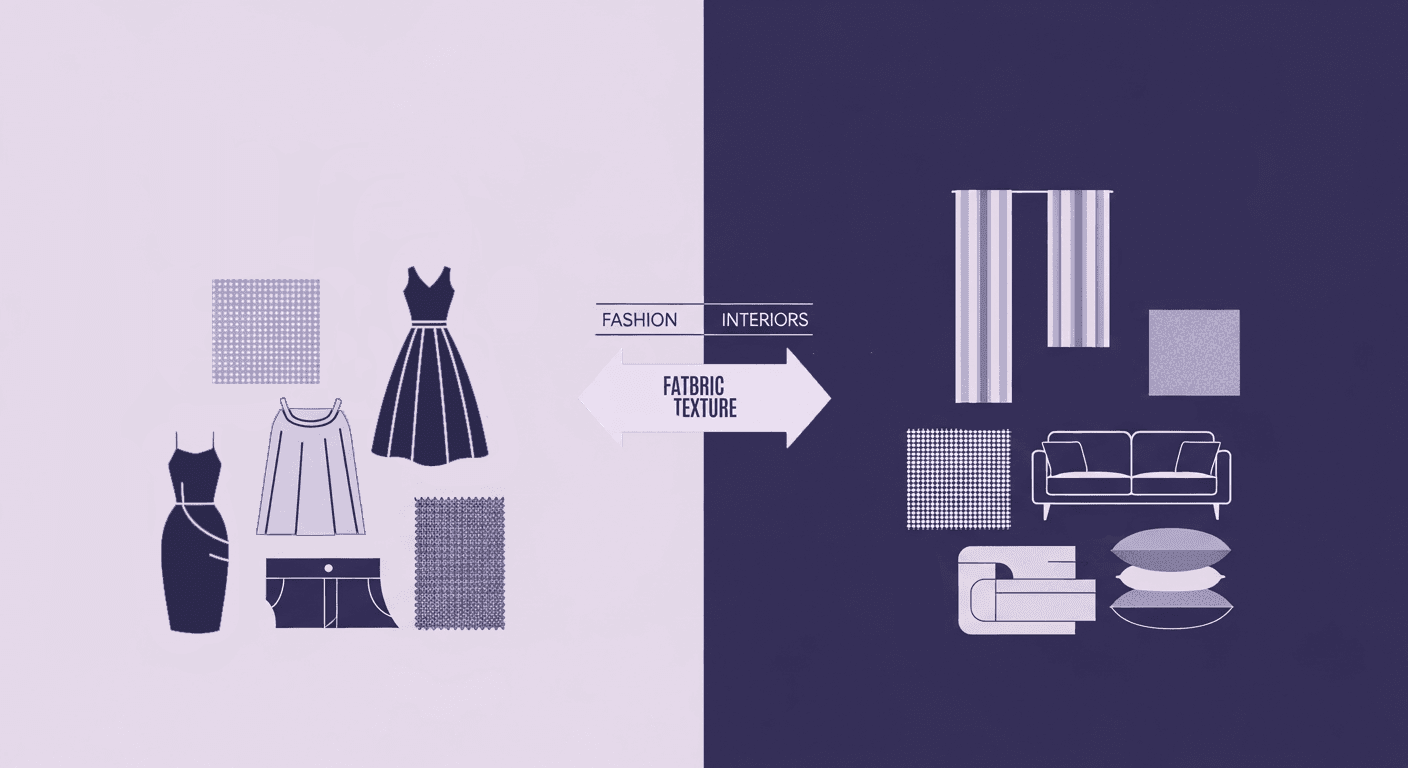

How Fabric Texture Shapes Design Strategy in Fashion and Interior...

Fabric textures

3D textures

Mira Kapoor

Dec 10, 2025

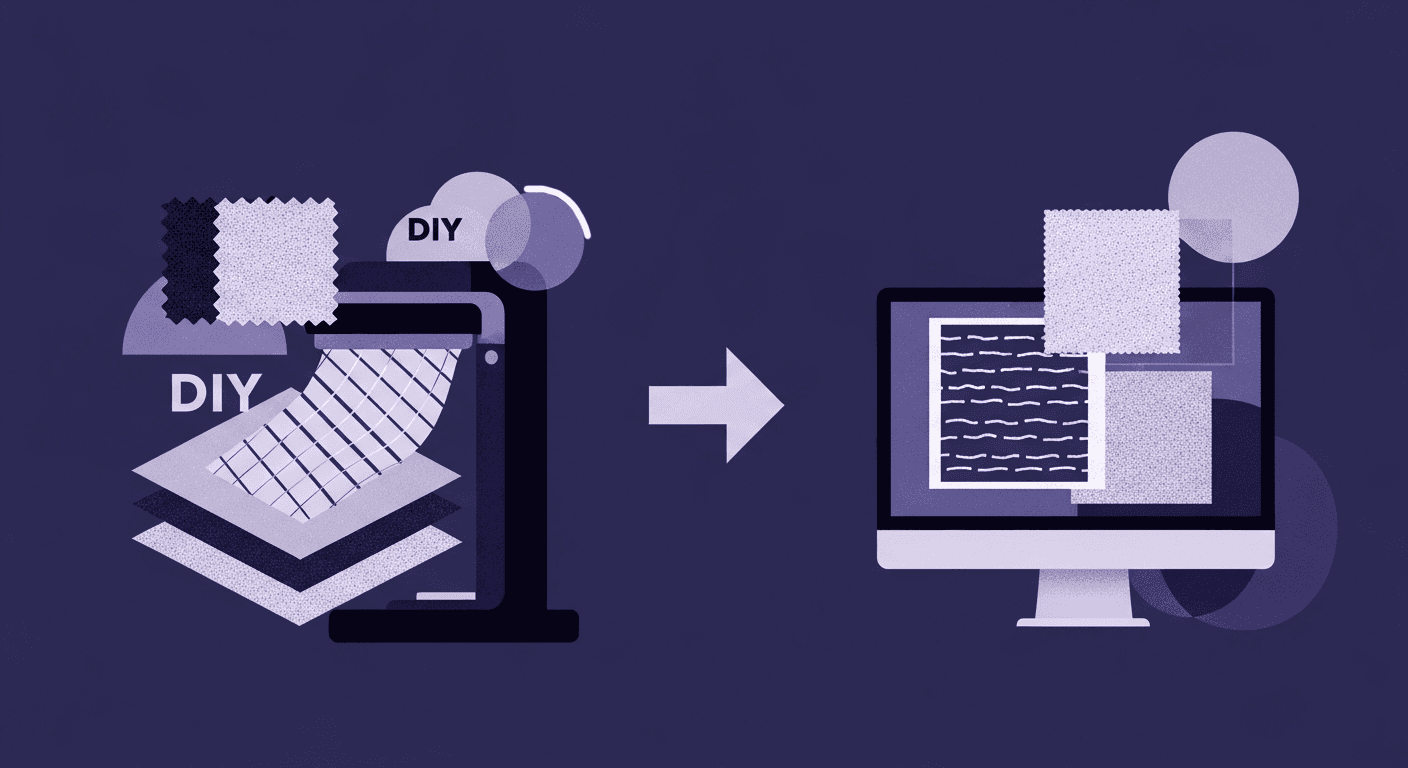

DIY Textile Texture Techniques That Make Digital Designs Come Ali...

Fabric textures

Texture creation

Max Calder

Dec 8, 2025

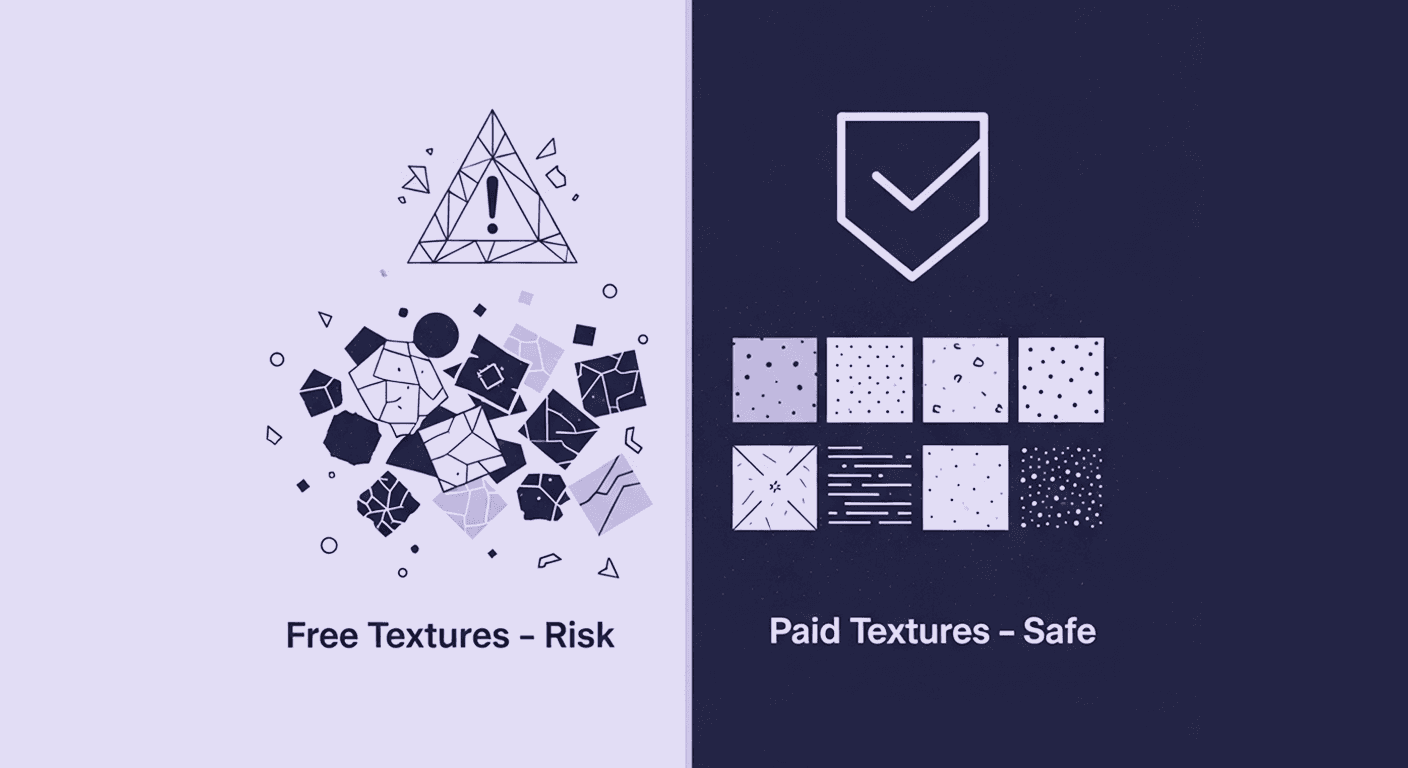

Cost vs. Quality: A Decision Framework for PBR Textures

PBR textures

3D textures

Mira Kapoor

Dec 5, 2025