More Than Material: How Plastic Texture Design is Unlocking Sustainable Innovation

By Mira Kapoor | 19 September 2025 | 13 mins read

Table of contents

Table of Contents

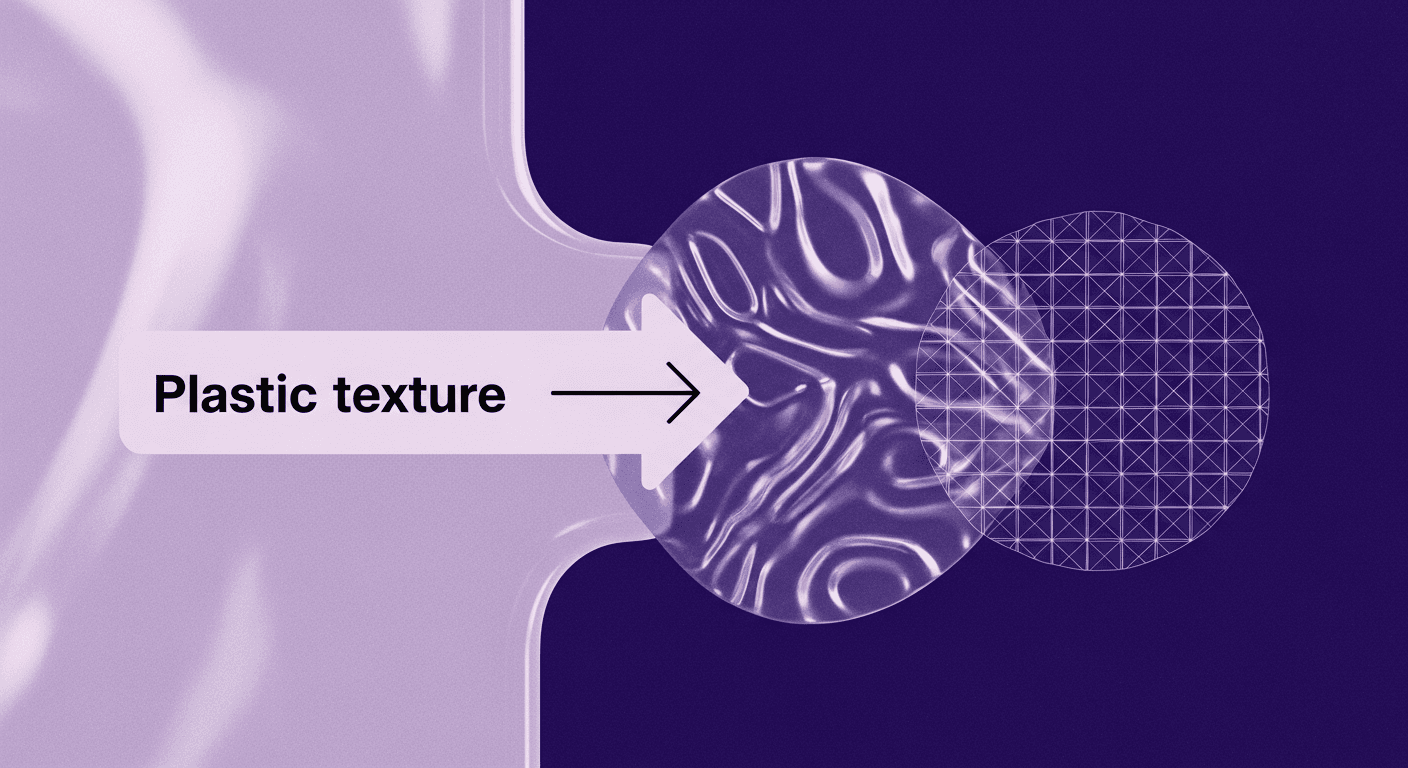

You’ve dialed in the color, perfected the gloss, and nailed the lighting. Then the physical prototype arrives, and the dashboard texture looks nothing like your render. That gap between digital and physical is where projects get delayed and rework begins. This article is about closing that gap. We’re going to unpack why plastic texture has evolved from a simple surface finish into a core design component that dictates a product's function, feel, and perceived value. We're moving beyond just mimicking old-world materials like leather and wood; today’s most innovative designs use textures born from advanced manufacturing, and understanding them is the key to making your visualizations not just beautiful, but believable.

Beyond smooth and shiny: Why plastic material texture is your new design superpower

Color and gloss can grab attention, but texture is what defines how a product feels and performs. In a world crowded with visually similar designs, the right surface finish can set your work apart, influencing usability, comfort, and emotional connection. Texture is no longer an afterthought, it’s a powerful storytelling tool hidden in plain sight.

How texture influences design functionality and user perception

Most artists think their work on plastic is done once the color and glossiness are dialed in. They’re right, but only if the goal is to create something that looks good from a distance. Up close, where products are held and used, the real story is told by the texture.

It’s easy to forget, but touch is one of our most primal senses. The psychological impact of a product’s feel is immediate and subconscious. A soft, yielding surface can communicate comfort and luxury, while a hard, rough texture might suggest durability and ruggedness. Think of it like audio in a film; you might not consciously notice it when it’s done right, but you definitely feel its absence or misapplication. This is the difference between a tool that feels like an extension of your hand and one that feels like a cheap piece of plastic.

For years, design choices were almost entirely visual. But we’re moving from a purely visual approach to one that embraces tactile feedback. Why? Because in a world saturated with sleek, glassy screens, a unique physical texture stands out. It creates a memorable, tangible connection with the user. That subtle grain on a camera body isn't just there to look good in a render; it’s a deliberate choice to inspire confidence when you hold it. It’s a shift from asking “How does it look?” to “How does it feel?”

This is where your role as a visualization artist becomes critical. You’re not just painting with light and color; you’re translating a physical, tactile experience into a visual medium. Understanding the why behind a texture choice is the first step to recreating it authentically.

The surprising link between texture and performance

Texture isn’t just about feeling premium. It’s a workhorse. The right surface finish can solve complex engineering and design challenges in ways that are both elegant and efficient. It’s where material science and design intent collide.

Consider these examples of textures doing the heavy lifting:

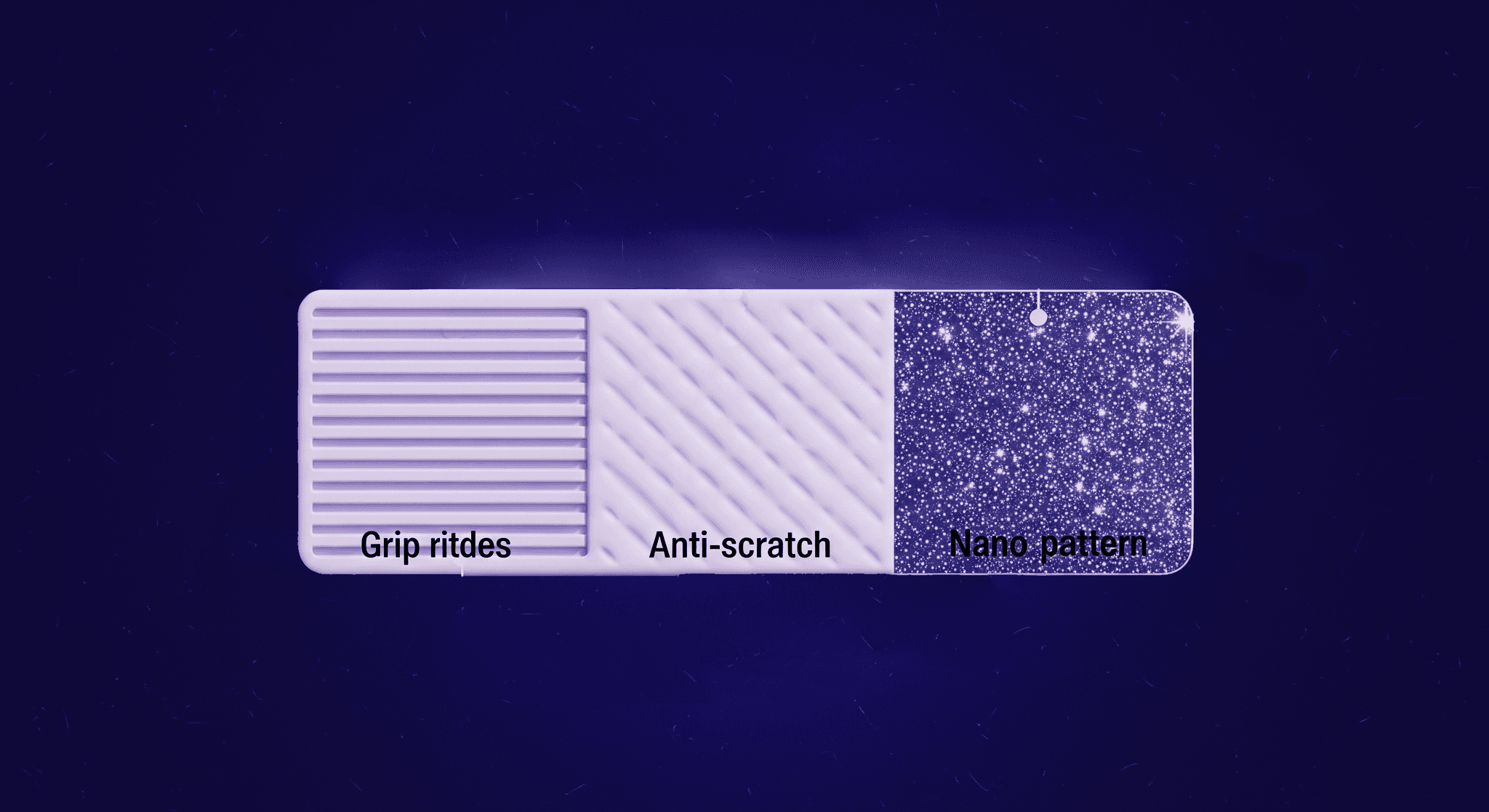

- Grip and control: The most obvious, but often overlooked, function. The stippled pattern on a power drill handle or the micro-texture on a game controller isn’t decorative. It’s a functional feature designed to channel sweat and increase friction, ensuring the user maintains control even in high-stakes situations. It’s performance you can feel.

- Durability and resilience: Think about modern luggage. That matte, patterned finish isn’t just a style choice. It’s engineered to scatter light and hide the inevitable scuffs and scratches from travel. A perfectly smooth, glossy suitcase would look wrecked after one trip. The texture adds a layer of visual resilience, keeping the product looking newer for longer.

- Light diffusion: In automotive lighting or consumer electronics, managing light is everything. A precisely molded micro-texture on the inside of a car’s tail light lens can diffuse the light from an LED, turning a harsh point source into a soft, uniform glow. The texture itself becomes a key component of the optical system.

Changing a material's texture can solve design challenges that seem completely unrelated. Does a device feel flimsy? A matte, micro-textured finish can increase its perceived density and quality. Does a component overheat? A texture that increases surface area can improve passive cooling. Before you change the material or the form, ask what the texture can do for you. It’s often the fastest, most effective tool in your arsenal.

So, we've unpacked why texture is a core design element. Now, let’s look at the incredible technology that’s making these new tactile experiences possible.

The tech behind the touch: Material texture innovation in action

The next generation of plastic textures isn’t happening by chance, it’s being engineered at the microscopic level. Advances in material science, manufacturing, and 3D modeling are unlocking possibilities that once seemed impossible. From bio-inspired surfaces to self-healing finishes, these innovations are reshaping how products look, feel, and function.

What are the latest innovations in plastic material textures?

The world of plastic textures is moving far beyond simple stipples and grains. We're in an era of engineered surfaces, where the texture is as technologically advanced as the product itself. Here’s a look at what’s bubbling up in material science labs and starting to appear in cutting-edge products:

- Bio-inspired surfaces: Nature has had billions of years to perfect functional surfaces. Designers are finally catching up. We’re seeing plastics that mimic the microscopic structure of lotus leaves to create superhydrophobic (water-repelling) and self-cleaning finishes. Others borrow from shark skin, using specific riblet patterns to reduce drag in automotive or aerospace applications. These aren’t just patterns; they’re microscopic functional systems.

- Self-healing finishes: Scratches and scuffs are the enemy of any pristine surface. New polymer composites are being developed with self-healing properties. When a minor scratch occurs, the material can reflow or rebond to repair the damage, dramatically extending the aesthetic life of a product. Imagine a car’s interior trim or the back of a phone that looks new for years, that's the promise.

- Soft-touch composites: This is more than just a rubbery coating. Advanced techniques like co-injection molding allow manufacturers to fuse different polymers at a molecular level. This creates a single part with distinct zones, a rigid structural core, and a soft, durable, and chemically bonded outer layer. It offers the best of both worlds: the pleasant haptics of a soft material with the structural integrity of a hard plastic.

Exploring texture-driven design innovation

The tools we use to create are just as important as the materials themselves. The real revolution in plastic material texture design is happening at the intersection of material science and advanced manufacturing. What was once impossible to model or manufacture is now becoming commonplace.

Modern injection molding, for example, has reached an incredible level of precision. Using techniques like laser ablation to etch the molds, engineers can create micro-textures with features smaller than the width of a human hair. This allows for surfaces that can control light, friction, and even airflow with unprecedented accuracy.

Then there's 3D printing. Technologies like MultiJet Fusion (MJF) and PolyJet are fundamentally changing the game for prototyping and even final production. Artists and designers can now create and test complex, variable textures in-house within hours. You can print a dozen different grip patterns for a new controller and actually feel them, rather than just guessing from a render. This rapid, iterative cycle from digital model to physical object and back again is compressing design timelines and unlocking new creative possibilities.

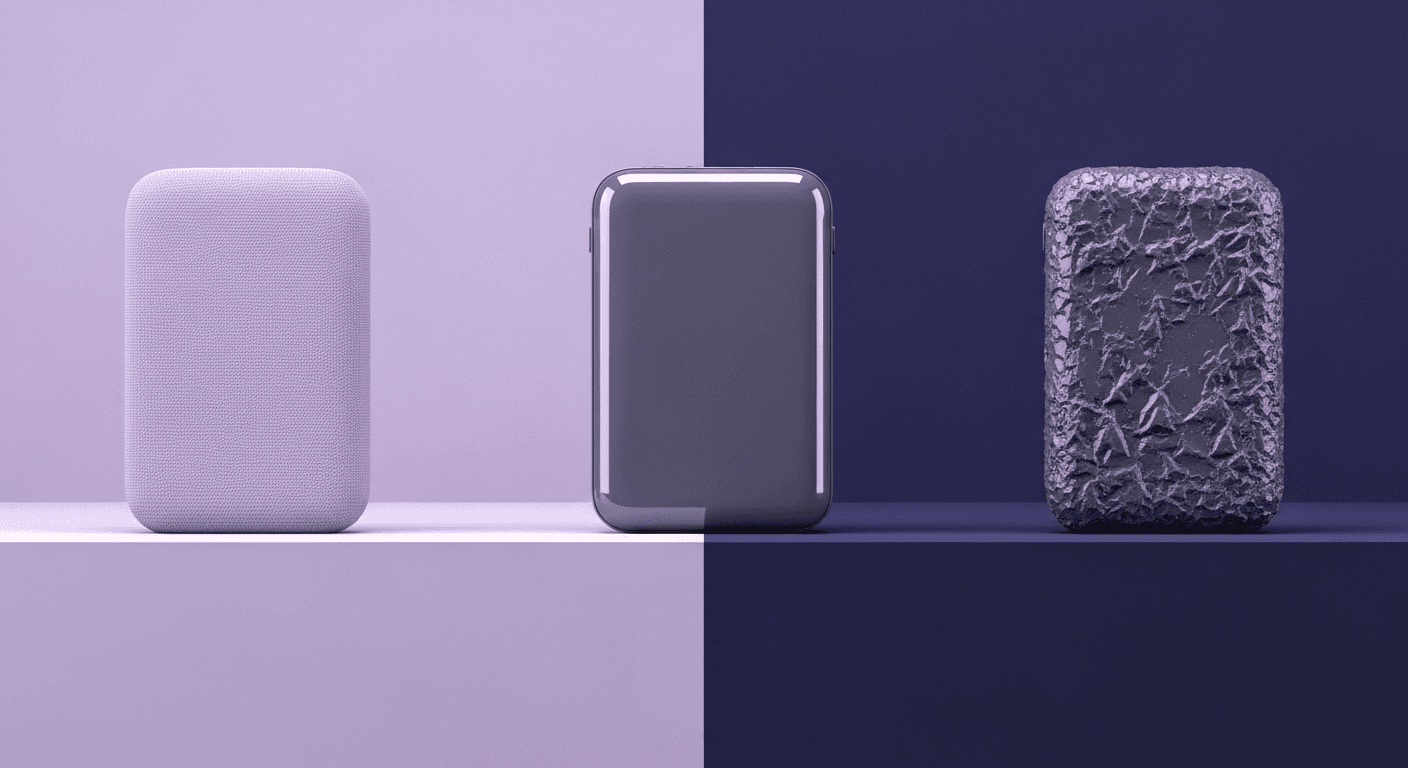

This technological leap marks a crucial shift in mindset. For decades, the goal of plastic texture was to mimic something else: wood grain, leather, or stone. We were trying to make plastic look like anything but plastic. Now, designers are embracing the material for what it is and exploring textures that are entirely new and digitally native. We’re moving from imitation to invention.

Now that we know the tech, let's see how it's being applied to transform real-world products you use every day.

From concept to reality: Transforming design through material texture manipulation

Innovation only matters when it works in the real world. Texture choices today are redefining product performance and perception across industries, from automotive interiors that feel premium to smartphone grips designed for precision handling. Understanding how these textures are applied bridges the gap between concept and consumer experience.

How texture changes impact design capabilities in the real world

Theory and technology are one thing, but the real test is how these innovations perform in the market. Texture is no longer a final, decorative touch; it’s a core part of a product’s identity and functionality. Let’s break it down with two clear examples.

Case Study 1: Automotive interiors and perceived value

This is your world. Think back to a budget car from the early 2000s. The dashboard was likely a single, vast piece of hard, shiny, grey plastic. It did its job, but it screamed “cheap.”

Now, step into a modern electric vehicle, even an entry-level one. The interior is a landscape of different textures. You’ll find a soft-touch, matte finish on the main dash to reduce glare and convey quality. There might be a laser-etched geometric pattern on the door trim that catches the light in a dynamic way. The center console could feature a fabric-like molded texture that feels warm and inviting. None of these surfaces is necessarily more expensive to produce in terms of raw materials, but their combined effect is transformative. They create a sense of sophistication and high perceived value. The texture tells a story of craftsmanship and thoughtful design, making the driver feel like they’re in a premium space. As a viz artist, capturing this interplay of textures is key to selling the feeling, not just the car.

Case Study 2: Consumer electronics and functional grip

Pick up your smartphone. Chances are, the smooth glass front is contrasted by a textured back or frame. Early smartphones were often glossy, slippery objects prone to being dropped. Designers quickly learned that texture was a functional necessity.

Today, you see a range of solutions. Some brands use a frosted or matte glass finish on the back, which resists fingerprints and provides a subtle, velvety grip. Others use precisely molded textures on the phone's frame to give your fingers a secure purchase point. This is texture as ergonomics. The same principle applies to TV remotes, game controllers, and professional cameras. The texture is strategically placed at key contact points to improve usability and create a sense of security and control. It’s a silent partner in the user experience.

The role of sustainable design textures in modern products

For a long time, recycled plastic brought to mind a specific, unappealing image: a dull, slightly off-color material that looked and felt inferior. That’s changing fast. Smart companies are now turning sustainability into a design feature, and texture is leading the charge.

Instead of trying to hide the unique composition of recycled materials, designers are celebrating it. They are creating products where the small flecks of color from different plastic sources create a beautiful, terrazzo-like effect. This unique finish becomes a visual badge of honor, instantly communicating the product's eco-friendly credentials. It transforms a potential flaw into a desirable, one-of-a-kind aesthetic.

We're also seeing new molding techniques that press recycled plastics in ways that create organic, wood-like grains or layered, geological patterns. This approach balances aesthetics with environmental responsibility. The texture tells a story not just of quality, but of circularity. It shows that sustainable design doesn't have to be a compromise; it can be a source of beauty and innovation.

Seeing these complex surfaces in the wild is inspiring. But it also presents a new challenge: how do you get them into your workflow and keep your digital assets perfectly in sync with the physical world?

Your workflow, upgraded: Managing your material library for the future

As plastic textures become more complex and diverse, your material library can no longer be an afterthought. Building a future-ready repository ensures your designs stay consistent, accurate, and adaptive to fast-moving trends. With procedural tools, scanning techniques, and disciplined organization, your library becomes the foundation of seamless, believable visualization.

Innovative approaches to plastic material design for visualization artists

Capturing the subtle, anisotropic sheen of a laser-etched texture or the random flecks in a recycled composite is tough. Your old workflow of just tweaking roughness maps won’t cut it anymore. It’s time to upgrade your approach.

Here are some strategies for digitally capturing and recreating these complex new surfaces:

- Embrace proceduralism: Instead of relying on tiled, photographic textures, learn to build materials procedurally. Tools like Substance 3D Designer are essential here. They let you create infinitely variable and high-resolution textures from scratch. You can build a base material for a specific type of injection-molded plastic and then add layers for surface imperfections, patterns, and weathering. It gives you ultimate control and avoids ugly tiling artifacts.

- Leverage 3D scanning: For truly unique or organic surfaces, nothing beats capturing the real thing. Photogrammetry and dedicated 3D material scanners can capture not just the color (albedo) but also the precise height information (displacement/normal) and surface reflectivity (roughness/metallic). This is the ground truth. The data you capture can then be used to create a highly accurate digital twin of the physical material.

- Think in layers: The most realistic materials are rarely a single shader. Break down your materials into logical layers. A soft-touch dashboard might have a base polymer layer, a slightly different texture for the soft-touch coating, and then a final micro-grain layer to break up specular highlights. This mimics how materials are constructed in the real world and gives you more control points for fine-tuning.

Keeping your virtual models synced with physical prototypes is the holy grail. The goal is a perfect 1:1 match so that design reviews based on your renders are reliable. This requires a material library that’s as sophisticated and well-documented as the materials themselves.

Building a future-proof material library

Your material library is more than just a folder of files. It's a strategic asset. A well-organized, forward-thinking library saves you time, reduces errors, and allows you to react quickly to new design trends. Here’s how to build one that’s ready for the future of plastic material transformation.

First, get disciplined with your naming conventions and metadata. Don't just save a material as Soft_Black_Plastic.mat. Be specific. A better name would be TPE_Soft-Touch_Matte_1mm-Stipple_Automotive-Dash.mat. Use metadata to tag your assets with crucial information: manufacturing process (e.g., injection-molded, 3D printed), sustainability info (e.g., recycled PET, bio-based), and even haptic properties (e.g., soft, grippy, smooth). This makes your library searchable and scalable.

Next, centralize your resources. Your library should be the single source of truth for materials across your team. Use tools that allow for version control and easy sharing. Look to high-quality online libraries like Poliigon or Quixel Megascans for best-in-class base materials, but always tweak them to match your specific project needs. Don't just download and apply; deconstruct and learn from them.

Finally, stay curious. The world of material innovation is moving incredibly fast. Follow material science publications, attend webinars from manufacturing companies, and request physical samples whenever you can. Touch and feel the materials you’re trying to recreate. Your ability to observe, translate, and organize these emerging trends into your digital toolkit is what will set you apart. Your material library isn’t just a reflection of past projects; it’s your roadmap for what’s next.

Your new role: The material translator

We’ve moved way past thinking of texture as just a roughness map you tweak at the end of a project. As we’ve unpacked, it’s a core component of a product’s performance, its feel, and its story.

This changes your role. You’re no longer just recreating a surface; you’re translating intent. You’re the one who communicates the story behind a bio-inspired grip, a self-healing finish, or a recycled composite that wears its origins with pride. That’s a huge shift from technician to storyteller.

The material library you build is your dictionary for this new language. Every procedural setup you master and every 3D scan you perfect makes you a more fluent, more valuable translator between the physical and digital worlds.

Ultimately, this isn’t just about closing the gap between the render and the prototype. It’s about building the bridge. And you’re the one holding the blueprints.

Mira Kapoor

Mira leads marketing at Texturly, combining creative intuition with data-savvy strategy. With a background in design and a decade of experience shaping stories for creative tech brands, Mira brings the perfect blend of strategy and soul to every campaign. She believes great marketing isn’t about selling—it’s about sparking curiosity and building community.

Latest Blogs

How 4K Seamless Textures Transform Flat CG Into Tangible Fabric

PBR textures

Fabric textures

Max Calder

Nov 21, 2025

Beyond Color and Gloss: How Plastic Texture Tells Your Product's ...

Product rendering

Texture creation

Max Calder

Nov 19, 2025

Decode Plastic Material Texture: The Team Language That Prevents ...

Product rendering

Texture creation

Mira Kapoor

Nov 17, 2025