The Wood Veneer Texture Design Trends Redefining Spaces in 2024

By Max Calder | 17 October 2025 | 14 mins read

Table of contents

Table of Contents

The standard wood finishes that felt classic a few years ago are starting to feel predictable. And in a market that moves this fast, predictability is a risky place for any product line to be. This guide is built to get you ahead of the curve. We’re unpacking the key wood veneer texture design trends for 2024, focusing on the innovative patterns, tech-driven techniques, and sustainable finishes that will define forward-thinking design. We’ll dig into everything from algorithm-driven parametric surfaces to the psychology behind an ultra-matte finish, giving you the practical insights needed to make strategic choices that truly resonate.

The new look: Key wood veneer texture design trends for 2024

Wood design is no longer about playing it safe; textures are stepping into the spotlight as a true design language. The latest veneers are being used not just as finishes, but as expressive elements that shape how products and spaces are experienced. This section looks at the bold directions that are reshaping the surface aesthetics of modern wood.

Exploring innovative wood veneer patterns taking center stage

Flat, uniform wood surfaces have had their moment. They’re safe, predictable, and frankly, a little boring. For 2024, the game is all about depth, rhythm, and dimension. It's about creating surfaces that you want to reach out and touch. Here’s what’s leading the charge.

First up, fluted and reeded surfaces are back, but not like you remember them. This isn’t your grandparents’ wood paneling. Think crisp, architectural lines that add a sense of order and sophistication. Fluting with its concave grooves and reeding with its convex, rounded profiles play with light and shadow in a way flat veneers just can’t. They create a visual rhythm that can make a piece of furniture or a feature wall feel both modern and timeless. The reason this works so well now is its versatility. A tight, narrow reeding can feel sleek and almost futuristic, while a wider, bolder flute can evoke a sense of Art Deco luxury. It’s a pattern that plugs directly into the modern desire for structured, yet organic, design.

Next, we’re seeing a surge in geometric and parametric designs. This is where technology really starts to show off. Instead of relying solely on the natural wood grain, designers are using algorithms to generate complex, non-repeating patterns. Imagine chevrons that shift in scale, interlocking hexagons, or flowing, wave-like forms carved directly into the veneer. Parametric design allows for a level of customization that was previously unthinkable. You’re not just picking a pattern; you’re defining the rules that create it. This trend is a direct response to the demand for personalization and uniqueness. For a product line, this means you can offer bespoke textures that make a product feel one-of-a-kind, a massive differentiator in a crowded market.

Finally, there’s a renewed love for deeply brushed and wire-scraped textures. In a world of slick digital screens, people are craving tactile, authentic materials. These techniques do more than just mimic an aged look; they physically alter the surface of the veneer, scraping away the softer wood to reveal the harder grain. The result is a rugged, honest texture that tells a story. It’s perfect for creating a sense of warmth and rustic comfort, tapping into the biophilic design trend that seeks to connect us with nature. This isn’t about making something look old for the sake of it. It’s about celebrating the inherent character of the wood and creating a surface that feels real and grounded.

Beyond the grain: Color and finish innovations

Texture isn't just about the physical shape of the surface; it’s also about how that surface interacts with light. And that’s where color and finish come in. The right finish can either amplify a texture or create a subtle counterpoint. For 2024, the innovations here are pushing veneers into entirely new aesthetic territories.

One of the biggest shifts is toward ultra-matte finishes that absorb light. You’ve probably seen this in paints and automotive finishes, and now it’s transforming wood. Unlike satin or semi-gloss, an ultra-matte or dead flat finish has a very low sheen, which gives the wood a raw, almost velvety appearance. The reason this is so effective is that it makes the color and grain the hero. Without reflections getting in the way, the viewer’s eye is drawn to the natural pattern and the physical texture of the wood. This works especially well with darker woods or muted, earthy tones, creating a sophisticated and calming effect that feels incredibly modern.

On the complete opposite end of the spectrum are high-gloss and liquid-metal effects. A deep, mirror-like gloss finish can turn a wood veneer into a statement of pure luxury. Think piano-black finishes or rich burl woods polished to a glass-like sheen. This isn't just about being shiny; it's about creating depth. The multiple layers of lacquer create a sense of looking into the wood, not just at it. And for a truly cutting-edge look, some finishes now incorporate metallic particles to create a liquid-metal effect, where the wood grain seems to shimmer with a subtle, pearlescent glow. It’s a bold move that blurs the line between a natural material and a futuristic one.

Finally, we’re seeing more nuanced and layered approaches with two-tone and cerused finishes. A cerused finish, traditionally done with oak, involves rubbing a contrasting pigment (often white or light gray) into the open grain of the wood. This technique beautifully highlights the wood’s natural texture by making the grain pop. It adds a layer of visual complexity and softness. Two-tone finishes take this a step further, combining stains or colors to create contrast. This could be a dark stain with a lighter cerused grain, or even a subtle color wash that lets the natural wood tone show through. It’s a fantastic way to add character and depth without overpowering the material itself.

The green veneer: How sustainable wood surface design is driving innovation

Sustainability isn’t just shaping how veneers are sourced; it’s reshaping how they look and feel. Eco-conscious practices are pushing designers to uncover beauty in reclaimed materials, natural imperfections, and low-impact finishes. These choices aren’t simply ethical; they’re introducing new textures, grains, and finishes that elevate products with authenticity. Here, we’ll see how green innovation is driving fresh design possibilities.

Eco-friendly veneer production and its impact on texture

Sustainability in design has moved past the talking points. It’s no longer a checkbox; it’s a core driver of innovation, and it's fundamentally changing the way we think about wood veneer textures. This isn’t about sacrificing aesthetics for ethics; it’s about finding new beauty in responsible practices.

The most direct impact comes from techniques using reclaimed and certified woods. Reclaimed wood, sourced from old buildings or structures, comes with a built-in story. Its texture is a map of its previous life. Nail holes, weathering, and color variations aren't defects; they're features. Designers are leaning into this, preserving the wood's history to create surfaces with unmatched character. Similarly, veneers from FSC-certified forests often showcase species with unique grain patterns that were previously overlooked in favor of more uniform options. This shift encourages biodiversity and brings a wider, more interesting palette of natural textures to the forefront.

It's not just the wood itself; it's what you put on it. The move toward low-VOC (Volatile Organic Compound) finishes is also influencing texture. Traditional lacquers could create a thick, plastic-like shell. Many modern, eco-friendly finishes like hard-wax oils and water-based urethanes are designed to penetrate the wood and protect it from within. This results in a much more natural, tactile finish where you can still feel the grain under your fingertips. These finishes often have a lower sheen, aligning perfectly with the trend toward matte, authentic surfaces. So, the sustainable choice also happens to be the one that delivers a more sophisticated and honest textural experience.

Why sustainable wood veneer design trends matter for your product line

So, why should a product development manager care? Because your customers do. The demand for sustainable, transparently sourced products is not a fleeting trend; it’s a baseline expectation, especially among millennial and Gen Z consumers. Integrating verifiably eco-friendly veneers into your products is a powerful way to signal brand values and connect with this audience. It moves your product from being just an object to being part of a responsible ecosystem.

But this goes beyond marketing. There's a powerful aesthetic appeal to natural imperfections. In a world of mass-produced perfection, uniqueness is the new luxury. The slight variations in color, the interesting grain patterns, and the history embedded in reclaimed wood make each piece subtly different. This perfect imperfection creates a sense of authenticity and craftsmanship that can’t be replicated by a machine printing a repeating pattern. It tells your customers that they are getting something real and carefully considered. Embracing sustainable veneers isn’t just good for the planet; it’s a strategic design choice that builds brand loyalty and creates more compelling, story-rich products.

Tech at the surface: Modern wood texture techniques

Technology is unlocking a level of precision and creativity in veneers that was unimaginable a decade ago. Digital printing, CNC milling, and laser etching are turning simple sheets of wood into highly customizable design canvases. These tools give designers the ability to create patterns, textures, and finishes with surgical accuracy and limitless variation. In this section, we’ll dive into the cutting-edge techniques reshaping the surface of wood.

How are wood veneer textures changing in 2024 with new technology?

If sustainability is the soul of modern veneer design, technology is the nervous system. The tools at our disposal are evolving fast, breaking down the old barriers between an idea and a physical product. For anyone in Research & Design, this is where things get really exciting. Here’s what’s reshaping the possibilities.

Digital printing on wood veneer has matured far beyond just faking an exotic grain. The real innovation now is in creating hyper-realistic textures that are indistinguishable from the real thing or, more excitingly, abstract patterns that celebrate the digital origin. Imagine a veneer with a soft, watercolor-like wash of color overlaid on a subtle oak grain, or a geometric pattern printed with perfect precision before the final finish is applied. This allows for complete creative control, enabling you to prototype and produce custom surfaces that align perfectly with brand aesthetics without being limited by the natural availability of a specific wood.

For precision and customization, nothing beats laser etching and engraving. Lasers can create incredibly fine and detailed patterns with surgical accuracy. Think micro-textures, intricate logos, or delicate lacework patterns etched directly onto the wood surface. Because it's a digital process, you can go straight from a vector file in your design software to the production line. This workflow eliminates tooling costs and makes mass customization feasible. You could offer customers personalized engravings or create limited-edition product runs with unique surface designs, all managed through a digital pipeline.

And for true three-dimensional form, advanced CNC milling is opening up a new frontier. While CNC has been around for a while, the precision and complexity of modern 5-axis machines allow for the creation of deeply sculpted, continuous 3D surfaces. We’re talking about the parametric waves and complex geometric forms mentioned earlier. This technology can turn a flat sheet of veneered panel into a dynamic, topographic surface. It’s a process that merges the warmth of wood with the precision of high-tech manufacturing, creating architectural finishes that were impossible just a decade ago.

Wood texture innovation beyond traditional methods

This is where it all comes together. The most forward-thinking approach isn’t about choosing one technology; it’s about combining different technologies for unique layered effects. What happens when you take a CNC-milled panel with a wave pattern, and then use a laser to etch a delicate micro-texture onto the peaks of those waves? Or what if you digitally print a subtle color gradient onto a veneer before it's wire-brushed? This layering of techniques creates surfaces with unprecedented depth and sophistication. You’re building a texture with multiple layers of detail, appealing to the eye from a distance and to the touch up close.

The key to unlocking this potential is integrating digital workflows from design to production. Your design team can model these complex surfaces in software like Rhino or SolidWorks, simulate the play of light on them in a rendering engine, and then send the file directly to the CNC machine or laser cutter. This tight feedback loop between design and manufacturing dramatically shortens development time. It allows for rapid prototyping, you can 3D print a small-scale model to feel the texture, and ensures that the final product is exactly what the designer envisioned. This is how you move from just following trends to setting them.

From trend to strategy: Applying new textures in product development

Knowing what’s trending is only the first step; success comes from putting those trends to work strategically. The key is understanding the psychology of surfaces and aligning them with how people want to feel in a space or interact with a product. It’s also about bridging the gap between design ambition and manufacturing reality through collaboration and testing. This section unpacks how to transform veneer trends into smart, actionable strategies.

Understanding the design psychology of wood surfaces

Great, so we have all these new textures. Now what? Simply applying a trendy texture isn’t a strategy. The real skill lies in understanding why a texture works and how it makes people feel. This is the design psychology of wood surfaces.

Texture has a direct line to our subconscious. A rough, rustic, wire-brushed texture feels honest, warm, and grounding. It evokes a sense of nature and stability. A sleek, high-gloss, perfectly smooth surface, on the other hand, communicates precision, luxury, and modernity. It feels sophisticated and aspirational. The difference isn't just visual; it’s emotional. Texture influences mood and perception of value. A heavier texture can make a product feel more substantial and durable, while a fine, delicate pattern can suggest elegance and careful craftsmanship.

This means choosing the right texture for specific applications is critical. In a hospitality setting like a hotel lobby or a cozy restaurant, you might use deeply brushed veneers to create a welcoming and relaxing atmosphere. For a high-end corporate office, a sleek, fluted panel in a dark, matte finish might be used to convey authority and focus. In residential design, a soft, cerused oak could create a light, airy feel in a kitchen, while a dramatic parametric design could serve as a stunning feature wall in a living room. The texture should always serve the intended function and emotional goal of the space or product.

Integrating cutting-edge wood surface texture techniques into your workflow

Putting these insights into practice requires a bridge between the creative vision and the manufacturing reality. Getting this right is what separates the leaders from the followers.

One of the most important steps is fostering collaboration between design and manufacturing teams from day one. Your designers might dream up a complex CNC-milled surface, but the manufacturing team needs to weigh in on its feasibility, cost, and the best way to produce it at scale. A shared digital workflow is non-negotiable here. When both teams are working from the same 3D model, it eliminates the guesswork and ensures everyone is speaking the same language. The designer sees the aesthetic, and the engineer sees the toolpaths. Both are essential.

Finally, you need a robust process for prototyping and testing new architectural wood finishes. Before committing to a full production run, create physical samples. Use a small-scale CNC or laser cutter to produce swatches that the team can see and touch. Apply the intended finishes. Put them under different lighting conditions. Does the matte finish look too flat under office fluorescents? Is the high-gloss surface showing too many fingerprints? This iterative process of prototyping, testing, and refining is where you de-risk innovation. It allows you to move forward with confidence, knowing that the cutting-edge texture you’ve chosen will not only look incredible but will also perform perfectly in the real world.

So, what's your texture story?

Alright, we've covered a lot of ground from parametric patterns to ultra-matte finishes. But here’s the real takeaway: these aren't just separate trends to pick from a list. The most forward-thinking design doesn't come from just choosing one; it comes from combining them.

Think of these techniques as a new set of tools in your Research & Design toolkit. The real innovation happens when you start layering them. What story could you tell by laser-etching a micro-pattern onto a CNC-milled surface? How does a digitally printed gradient feel when paired with a deeply wire-brushed texture? This is where you move from following trends to creating a signature aesthetic that is uniquely yours.

By integrating these possibilities into a tight digital workflow, you're not just designing a surface; you're engineering a feeling. You’re building a faster, more collaborative bridge between a bold idea and a physical product. The surfaces of 2024 aren’t just about what’s new; they’re about what’s possible when technology and creativity work together. Now go build something people can't help but reach out and touch.

Max Calder

Max Calder is a creative technologist at Texturly. He specializes in material workflows, lighting, and rendering, but what drives him is enhancing creative workflows using technology. Whether he's writing about shader logic or exploring the art behind great textures, Max brings a thoughtful, hands-on perspective shaped by years in the industry. His favorite kind of learning? Collaborative, curious, and always rooted in real-world projects.

Latest Blogs

How Fabric Texture Shapes Design Strategy in Fashion and Interior...

Fabric textures

3D textures

Mira Kapoor

Dec 10, 2025

DIY Textile Texture Techniques That Make Digital Designs Come Ali...

Fabric textures

Texture creation

Max Calder

Dec 8, 2025

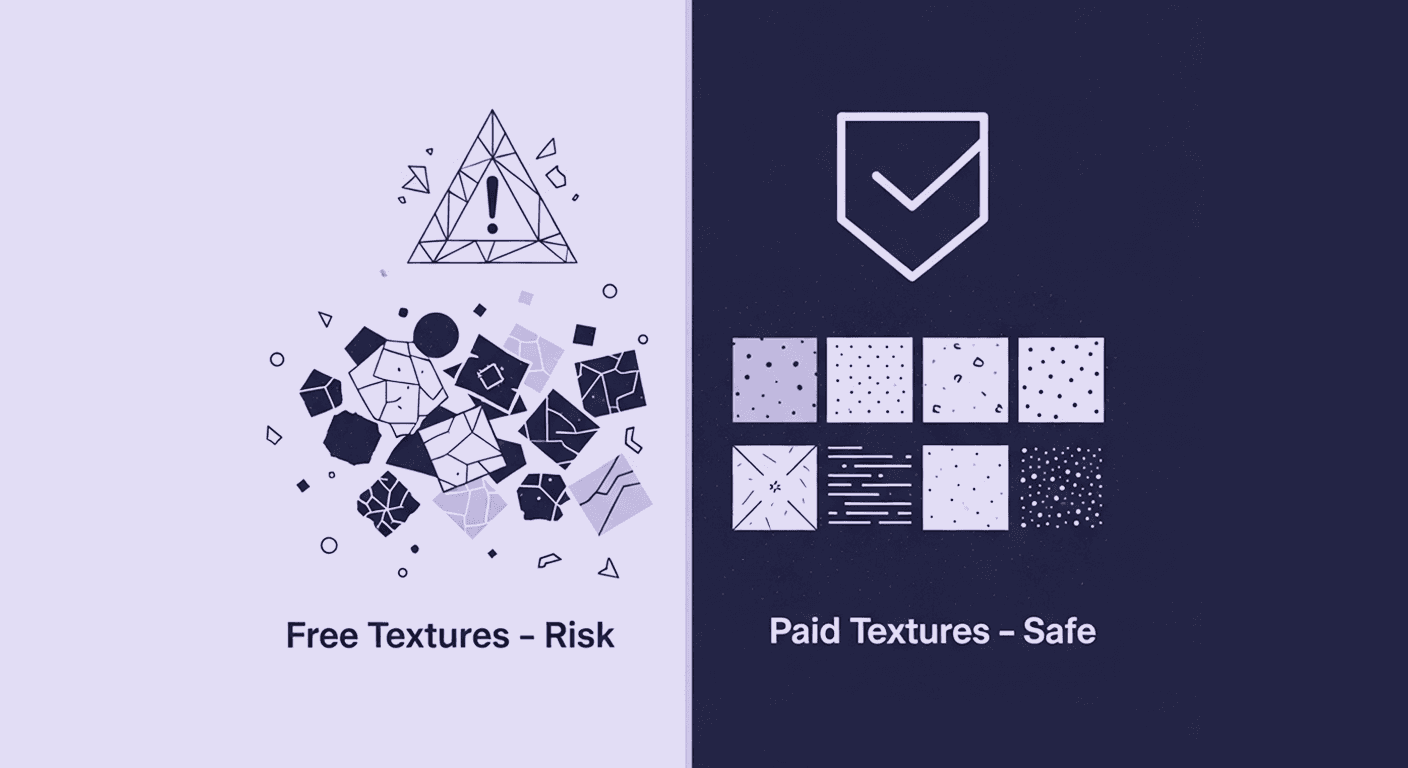

Cost vs. Quality: A Decision Framework for PBR Textures

PBR textures

3D textures

Mira Kapoor

Dec 5, 2025