Rethinking Wood Veneer: How Innovative Techniques Are Shaping Modern Furniture

By Mira Kapoor | 27 October 2025 | 13 mins read

Table of contents

Table of Contents

For a long time, wood veneer was a dirty word in quality furniture design, synonymous with peeling edges and cheap imitations. That reputation is officially outdated. This article unpacks how modern veneer has become a high-performance material engineered to solve the very challenges of consistency, complex forms, and sustainability that often limit solid wood. We'll explore the innovative techniques transforming surfaces and show you why it’s one of the smartest, most strategic materials in a modern furniture designer's toolkit.

Redefining the surface: What wood veneer in modern furniture means today

For years, wood veneer had a reputation problem. It was seen as the flimsy, peeling surface on cheap furniture, a weak substitute for the real thing. That reputation is officially outdated. Today’s wood veneer isn’t a compromise; it’s a high-performance material that unlocks design possibilities solid wood can’t touch. It’s engineered for flexibility, consistency, and sustainability, making it one of the smartest materials in a modern furniture designer’s toolkit.

Moving beyond the traditional: A quick primer on modern wood veneer techniques

Forget the thick, brittle sheets of the past. The wood veneer in modern furniture is a product of sophisticated manufacturing. We’re not just talking about slicing logs thinner. We’re talking about a complete reimagining of the material itself.

- Engineered veneers: Think of this as wood grain by design. Lesser-used, fast-growing wood species are dyed, layered, and re-sliced to create consistent, predictable, and often exotic patterns. This solves the age-old problem of sourcing perfectly matched solid lumber for large projects. You get the aesthetic you want, every single time.

- Flexible veneers: By bonding a thin layer of real wood to a paper or fleece backing, manufacturers create a material that’s as pliable as a textile. This allows designers to wrap veneer around tight curves and complex shapes without cracking or splitting, a feat that’s often impossible or prohibitively expensive with solid wood.

- Micro-veneers: These are exceptionally thin slices of wood, sometimes applied to non-traditional substrates like aluminum or recycled composites. They reduce weight, maximize material yield, and open the door for hybrid materials that blend the warmth of wood with the structural properties of metals or plastics.

These aren’t just incremental improvements. They represent a fundamental shift in how we can think about and use wood as a decorative surface. It's no longer just a plank; it's a canvas.

The material advantage: Why veneer is a smart choice for furniture design innovation

Choosing veneer isn’t about cutting costs; it’s about expanding creative freedom and technical performance. For a Research team, the advantages are too compelling to ignore.

First, design consistency. When you’re developing a product line, you need every piece to match. Sourcing solid wood with consistent grain and color is a logistical nightmare. Engineered veneers solve this, ensuring that the credenza manufactured in May looks identical to the one made in December. This predictability is crucial for scaling production without compromising quality.

Second, structural stability. Solid wood expands, contracts, and warps with changes in humidity. Veneer, when properly applied to a stable substrate like MDF or plywood, is far more resilient. It won’t split or cut, making it ideal for large, flat surfaces like tabletops and cabinet doors. This stability gives you a more durable, reliable product with fewer customer complaints down the line.

Finally, unprecedented creativity. Want to create a desk with a seamless, waterfall edge that curves 90 degrees? Or a reception counter with an undulating, wave-like face? Veneer makes it possible. It liberates designers from the constraints of solid wood's grain and rigidity, allowing for forms that are more fluid, more dynamic, and ultimately, more innovative.

In short, modern veneer gives you the aesthetic soul of wood backed by the brain of modern engineering. It’s time to stop thinking of it as a substitute and start seeing it as an upgrade.

The new aesthetic: Creative wood veneer applications

With the technical barriers removed, designers are pushing wood veneer into exciting new territory. The focus has shifted from simply covering a surface to transforming it. This is where wood veneer in modern furniture becomes less about imitation and more about imagination, creating aesthetics that are entirely new.

Sculpting with veneer: Creating curves, waves, and 3D textures

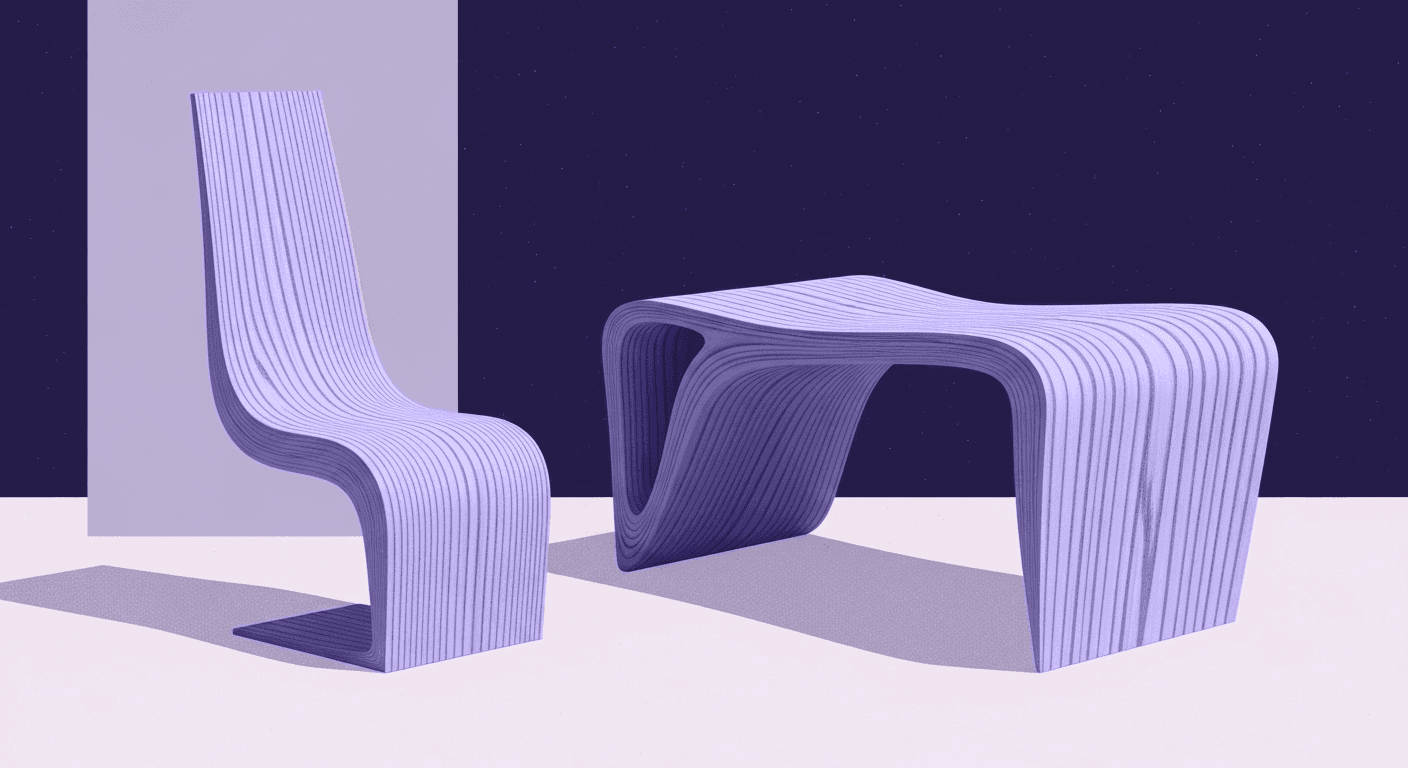

The biggest game-changer is the ability to treat veneer like a second skin for furniture. Thanks to flexible backings, designers can now specify complex, organic forms without worrying about the material breaking. Think of conference tables with bases that flow like ribbons or cabinet fronts with carved, three-dimensional patterns.

This is achieved by pressing veneer onto pre-molded substrates. The result is a surface that appears to be sculpted from a single block of wood, but without the weight, cost, or waste. For example, a leading contract furniture brand developed a line of office pods featuring sound-dampening, faceted wall panels. By using a flexible oak veneer over a molded composite core, they created a visually stunning and acoustically functional product that would have been impossible with solid timber. It’s a workflow that marries the best of digital fabrication with the timeless appeal of wood.

Playing with patterns: Marquetry, inlay, and digital grain manipulation

Patterning is no longer limited to the natural grain of the wood. Modern techniques have revitalized age-old crafts and invented new ones.

- Modern marquetry: Laser cutters now allow for incredibly intricate marquetry and inlay designs with pinpoint precision. Designers are combining different wood species, metals, and even colored resins to create geometric patterns, abstract art, and detailed logos directly on the furniture surface. This turns a simple tabletop into a narrative piece.

- Digital grain manipulation: Engineered veneers take this a step further. What if you could design your own wood grain? By digitally controlling the dyeing and layering process, manufacturers can now create patterns that don't exist in nature perfectly straight grains, exaggerated burls, or even subtle gradients. This allows for a level of brand-specific customization that was previously unimaginable.

Imagine specifying a unique wood grain that becomes a signature element for an entire furniture collection. That's the level of control now available.

Innovative surface treatments: Dyes, etching, and translucent finishes

Perhaps the most exciting frontier is in surface treatments. The raw veneer is just the starting point; it’s what you do to it that creates a truly innovative surface.

Designers are moving beyond traditional stains and lacquers to explore finishes that alter the wood's fundamental appearance. Deep-penetrating dyes can imbue veneers with rich, vibrant colors from deep indigo to slate gray while still allowing the natural grain to show through. This maintains the texture of wood but breaks free from the traditional color palette.

Laser etching is another powerful tool, allowing for fine-line patterns, textures, or branding to be permanently burned into the surface. Some designers are even experimenting with translucent veneers. By slicing the wood paper-thin and bonding it to a glass or acrylic substrate, they can create luminous panels that can be backlit, turning a simple wall panel or cabinet door into a light fixture. This is one of the most compelling innovative wood veneer design trends, blending material, light, and structure into one.

These creative applications aren't just novelties; they are powerful tools for creating furniture that is memorable, functional, and deeply connected to a modern design language.

The sustainability angle: Why eco-friendly furniture materials matter

Innovation isn't just about aesthetics or performance; it's about responsibility. As consumers and regulators demand greater environmental accountability, the material choices we make have never been more critical. This is where wood veneer shifts from a clever design choice to an essential one. It is, quite simply, one of the most sustainable ways to bring the beauty of wood into a space.

Doing more with less: How wood veneer maximizes a precious resource

The fundamental principle of sustainability is to maximize resource efficiency, and veneer is a masterclass in this. A single log can produce an exponentially larger amount of surface material as veneer than as solid wood. Think about it this way: slicing a one-inch-thick plank from a log yields exactly that one plank. Slicing that same inch into veneer can produce 30-40 sheets of material.

This means a single, responsibly harvested tree can be used to create dozens of pieces of furniture, not just one or two. It allows designers to specify rare or exotic woods with a clear conscience, knowing they are using a tiny fraction of the resource. This isn't about stretching a material; it's about respecting it. You get all the visual impact of a beautiful hardwood while preserving the forest it came from.

The lifecycle of a surface: Recyclability and lower carbon footprints

The sustainability benefits extend across the entire product lifecycle. Because veneer is so much lighter than solid wood, it significantly reduces the carbon footprint associated with transportation from the forest to the factory and from the factory to the customer.

Furthermore, when bonded to substrates like particleboard or MDF made from recycled wood fibers, veneer becomes part of a circular material system. At the end of its life, a veneered panel can often be recycled or repurposed more easily than many solid wood products, which may be treated with heavier, more penetrating finishes. This lifecycle thinking is essential for any Design manager looking to build products for the future, not just for the next sales quarter.

Certifications that count: Sourcing sustainable wood veneer for your projects

Making a sustainable choice requires trust and verification. For Design managers and designers, specifying veneers with credible certifications is non-negotiable. It’s the only way to ensure the material comes from a well-managed forest and a transparent supply chain. These are the two primary certifications to look for:

- Forest Stewardship Council (FSC): This is the gold standard for responsible forestry. FSC certification ensures that the wood is harvested in a way that protects biodiversity, respects the rights of indigenous peoples, and maintains the ecological health of the forest.

- Programme for the Endorsement of Forest Certification (PEFC): Like the FSC, the PEFC is an international non-profit that promotes sustainable forest management through third-party certification.

When you specify FSC- or PEFC-certified veneer, you are doing more than just sourcing eco-friendly furniture materials; you are sending a clear signal to the market that your company values sustainability. It’s a mark of quality and a powerful part of your brand’s story.

From concept to factory floor: Bridging design and manufacturing

An innovative idea is only as good as its execution. For a Product Designer, the real challenge isn’t just discovering new materials; it’s integrating them into a scalable production workflow. The gap between a designer’s vision and the factory’s capabilities is where great concepts often fail. Closing that gap is essential for turning creative veneer applications into successful products.

How to use wood veneer in contemporary furniture design for scalability

Moving from a one-off prototype to a full production run requires designing for manufacturability from day one. When working with innovative veneers, this means thinking beyond the surface.

- Substrate is everything: The performance of the veneer is completely dependent on the substrate it’s bonded to. For flat surfaces requiring stability, a high-quality MDF or particleboard is often the best choice. For curved applications, a flexible “bender” plywood or a molded composite core is necessary. The choice of substrate impacts weight, cost, durability, and the manufacturing process, so it must be a core part of the initial design conversation.

- Mind the edge: How you finish the edge of a veneered panel is a critical detail. Will you use a matching veneer edge banding for a seamless look, or will you leave the layered plywood edge exposed for a more modern, honest aesthetic? This decision affects both the visual outcome and the production complexity.

- Standardize for efficiency: If you're using a laser-etched pattern or a custom-dyed veneer, work with your supplier to establish clear standards for color and pattern consistency. Develop a master sample that serves as the benchmark for quality control. This prevents variations between production batches and ensures the final product matches the original design intent.

Thinking through these practical details early in the process prevents costly surprises on the factory floor and makes innovation repeatable.

Technical talk: Specifying innovative veneers for production teams

Clear communication between the design studio and the manufacturing team is vital. A beautiful rendering is useless if the production team doesn’t have the technical information to build it. Your specification sheet for an innovative veneer product should be airtight.

Include these key details:

- Veneer species & cut: e.g., “FSC-certified Rift Cut White Oak.”

- Supplier & product code: For consistency in sourcing.

- Grain direction: Indicate clearly on all drawings how the grain should run.

- Substrate material & thickness: e.g., “¾ inch MDF with CARB Phase 2 compliance.”

- Adhesive type: Specify the correct adhesive for the application (e.g., PVA vs. contact cement).

- Finish specification: Don’t just say “clear coat.” Specify the type (e.g., “post-catalyzed conversion varnish”), sheen level (e.g., “20% sheen”), and number of coats.

- Edge banding details: Specify material, thickness, and application method.

Providing this level of detail removes ambiguity and empowers the production team to execute your vision accurately. It transforms the relationship from a simple handoff to a true collaboration.

Case studies: Brands winning with innovative and sustainable furniture surfaces

Theory is good, but proof is better. Let’s look at how leading brands are successfully using these techniques.

- Case Study 1: The modular office system. A major contract furniture company wanted to create a high-end, reconfigurable office system. By using a flexible, fleece-backed walnut veneer, they were able to design curved acoustic panels and storage units that felt both organic and sophisticated. The result: They won a major design award, and the product line exceeded sales projections by 30% in its first year. The use of a certified, sustainable furniture surface became a key marketing point.

- Case Study 2: The direct-to-consumer credenza. An online furniture brand sought to differentiate itself with a signature look. They worked with a veneer supplier to develop an engineered veneer with a unique, smoky-gray grain pattern. This custom material was used across their entire case goods collection. The result: The distinct aesthetic reduced their marketing costs by creating a recognizable visual identity. Because they were designed for production, they were able to maintain a competitive price point while offering a product that looked far more expensive than it was.

From material to mindset: Putting veneer to work

So, what’s the real takeaway here? We’ve moved past the old idea of wood veneer as a simple substitute and repositioned it as a strategic tool. It’s no longer just a material; it’s the bridge connecting your most ambitious design concepts with your most pressing manufacturing and sustainability goals.

Think of it this way: modern veneer is the common language that can get your design studio and your factory floor on the same page. It’s the material that allows for both the sweeping curve in the rendering and the efficient production run on the assembly line.

The next time you’re mapping out a product line, don’t just ask what material to use. Ask how a material can solve multiple problems at once. The techniques we’ve covered aren’t just for creating beautiful surfaces; they’re a roadmap for building more innovative, sustainable, and manufacturable products. You’ve got the insights. Now, go build what’s next.

Mira Kapoor

Mira leads marketing at Texturly, combining creative intuition with data-savvy strategy. With a background in design and a decade of experience shaping stories for creative tech brands, Mira brings the perfect blend of strategy and soul to every campaign. She believes great marketing isn’t about selling—it’s about sparking curiosity and building community.

Latest Blogs

How Fabric Texture Shapes Design Strategy in Fashion and Interior...

Fabric textures

3D textures

Mira Kapoor

Dec 10, 2025

DIY Textile Texture Techniques That Make Digital Designs Come Ali...

Fabric textures

Texture creation

Max Calder

Dec 8, 2025

Cost vs. Quality: A Decision Framework for PBR Textures

PBR textures

3D textures

Mira Kapoor

Dec 5, 2025