Understanding the Story Behind Natural Color & Grain Variations of Wood Veneer

By Max Calder | 18 July 2025 | 11 mins read

Table of contents

Table of Contents

That moment you unroll a new batch of wood veneer and see all its so-called inconsistencies can be a little jarring. Your first instinct might be to see them as flaws to be managed or rejected. But what if those variations are actually your most powerful design tool? This guide is your new playbook for mastering wood veneer. We're not just going to look at pretty pictures of grain; we’re going to decode why those differences in color and pattern happen, and how you can strategically use them to your advantage. Think of this as the key to shifting from just specifying a material to truly designing with it, giving you the confidence to create products with an authentic character that stands out in a world of predictable uniformity.

So, what's really going on with wood veneer?

Ever unrolled a sheet of wood veneer and found it looks… different from the last one? Good. That’s the point. Most people think their job is to fight these inconsistencies, but the real secret is understanding them. You’re not looking at a manufactured product; you’re looking at a story.

Understanding the "why" behind natural wood variation

Think of a tree’s grain as its biography. Every line, swirl, and color shift is a record of its life. Was it a wet season or a dry one? What was the soil composition like? Did it grow fast and straight, or did it have to fight for sunlight?

- Tree growth & species: A fast-growing pine will have a wider, more open grain than a slow-growing, dense oak. Each species has its own genetic blueprint for grain patterns, from the straight-laced Ash to the dramatic swirls of Walnut.

- Environmental factors: The tree’s location is everything. A tree on a windy hill will develop a stronger, more complex grain (called figure) as it braces against the elements. The minerals in the soil directly influence the wood's color, which is why Walnut from Ohio looks different from Walnut from California.

Why inconsistency is actually the signature of authentic wood

In a world of mass-produced perfection, these variations are the ultimate mark of authenticity. They prove that the material is real, organic, and one-of-a-kind. When you see a subtle change in color or a knot in the grain, you’re not seeing a flaw, you’re seeing a chapter in the tree’s history. Embracing this natural wood variation is the first step to using veneer like a pro.

Now that you know why veneer has so much character, let's unpack the specific patterns you’ll actually be working with.

Grain: A visual field guide

Okay, so we know that every tree tells a story. But how do you learn to read it? It starts with identifying the three fundamental wood grain types. Think of these as the foundational styles you’ll build your designs upon.

The three core wood grain types you'll encounter

- Plain sawn (or flat cut): This is the most common cut and the one you’re probably most familiar with. It produces the iconic cathedral or flame-like pattern. It’s bold, dynamic, and delivers a classic wood look with maximum yield from the log.

- Quarter sawn: If you’re looking for something more architectural and reserved, this is your cut. Quarter sawing produces a tight, straight, linear grain. You’ll often see shimmering, iridescent flecks in woods like Oak, known as medullary rays. It’s clean, stable, and incredibly sophisticated.

- Rift sawn: This is the quietest of the three. Rift sawing produces an even, straighter grain than quarter sawing, but without the medullary ray flecks. It’s the most uniform and stable cut, but also the least common due to the amount of waste it produces. Use it when you need subtle texture without the drama.

Beyond the basics: A peek at wood figure characteristics

Sometimes, a tree's life is more interesting than just straight growth. Stress, injury, or genetic quirks can create stunningly beautiful anomalies. These aren't defects; they are some of the most prized and valuable wood figure characteristics in the world.

- Burl: This comes from a tree's response to stress like an injury or fungus, and results in a chaotic, swirling pattern of dense knots. It’s rare, complex, and absolutely mesmerizing on a large surface.

- Bird's eye: Found most often in Hard Maple, this figure looks like a collection of small, swirling eyes dotting the wood. Its cause is still debated, but its effect is undeniable elegance.

- Quilted: This figure, often seen in Maple and Mahogany, creates a wavy, three-dimensional, or bubbly appearance, almost like a draped fabric. It’s a showstopper, plain and simple.

Recognizing these patterns is a great start. But the real magic happens when you understand how the cut itself creates what you see.

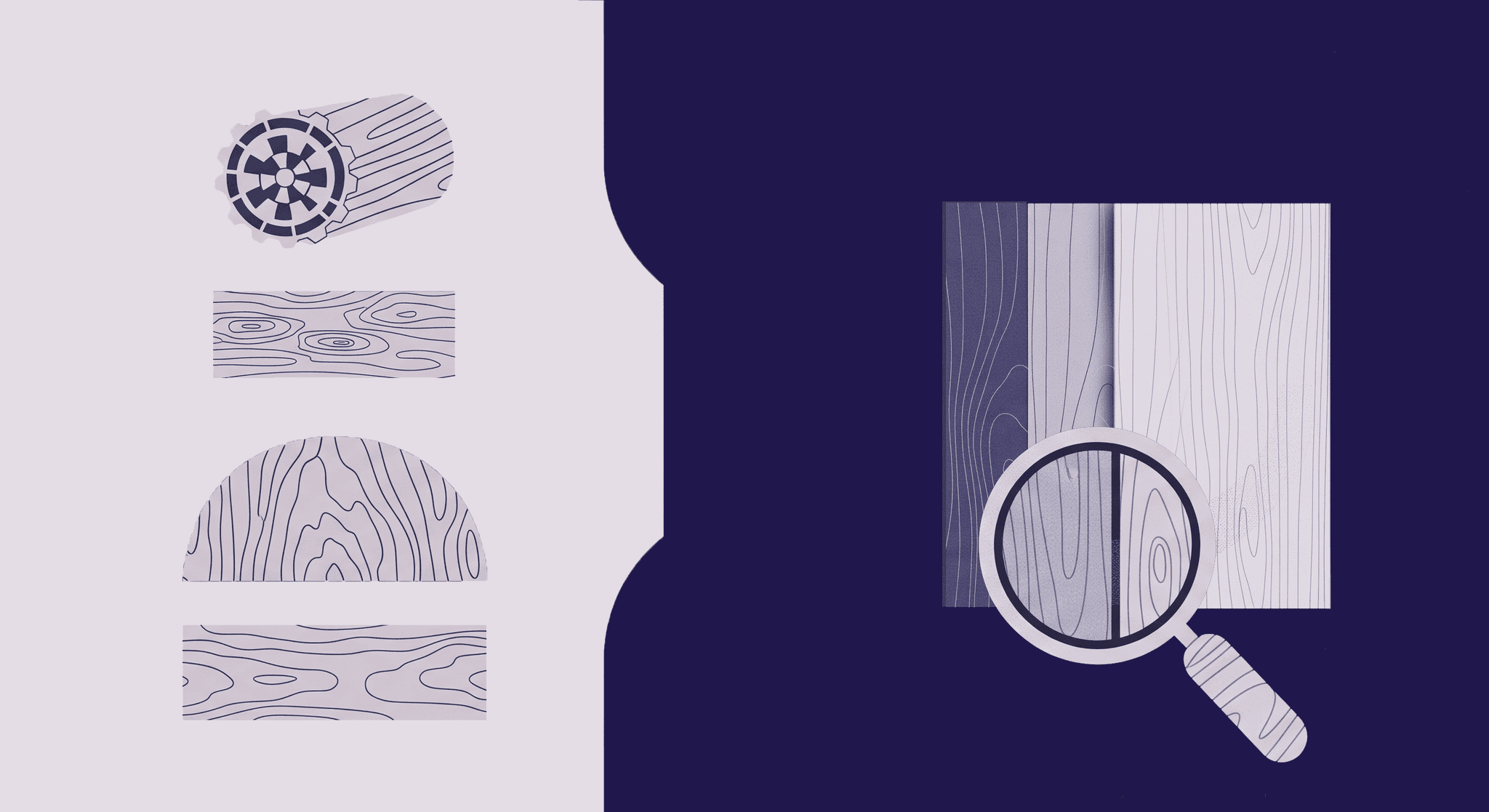

The cut is everything: How slicing creates the pattern

You can have the most beautiful log in the world, but the slicing method is what translates its potential into a usable veneer pattern. The geometry of the cut dictates everything. Here’s a simple breakdown of how different wood veneer cutting methods give you completely different visual results from the same tree.

How different cutting techniques affect wood veneer appearance

- Rotary cutting: Imagine putting a log on a giant lathe and peeling it like an apple. That’s rotary cutting. It produces a broad, wild, and often unpredictable grain pattern because it follows the log's annual growth rings. It’s the most efficient method and gives you very wide sheets, but the pattern can be overwhelming for some applications.

- Plain slicing (or flat slicing): This is the partner to plain-sawn lumber. The log is sliced parallel to its center, moving straight through the log. This is how you get that beautiful cathedral grain. It offers a great balance of classic wood pattern and material efficiency.

- Quarter slicing: To get that clean, linear look, the log is first cut into quarters (hence the name). Then, each quarter is sliced at a right angle to the growth rings. This process is what reveals the straight grain and the shimmering medullary rays in species like Oak. It’s less efficient but produces a highly sought-after, architectural look.

How the cut impacts both color and grain consistency

This is where we talk about the big trade-off in wood veneer color and grain variations. Your choice of cut directly determines how much visual drama or uniformity you get.

- For more drama: Rotary cutting gives you the most variation. The grain can change dramatically from one edge of the sheet to the other.

- For a classic look: Plain slicing is your middle ground. You get the iconic cathedral pattern, which has inherent variation but is more predictable than rotary.

- For more uniformity: Quarter slicing is the winner for consistency. Because you’re slicing across the growth rings in a straight line, the grain and color are incredibly consistent from one sheet to the next. This makes it ideal for large projects where you need a seamless, monolithic appearance.

Once you have your cut sheets, the next step is assembling them. And that’s an art in itself.

The art of the match: Assembling veneer with purpose

So, you’ve chosen your species and your cut. Now you have a stack of veneer leaves. How you arrange them can either create a seamless, flowing surface or a dynamic, energetic one. This is where veneer matching techniques come in. It’s less about hiding seams and more about using them to create a deliberate visual rhythm.

A practical guide to veneer matching techniques

- Book match: This is the most common technique. Every other leaf of veneer is flipped over, creating a mirrored, symmetrical pattern, like the open pages of a book. It’s perfect for highlighting the beauty of a cathedral grain and creating a strong focal point.

- Slip match: In a slip match, the leaves are laid side-by-side in the same orientation without being flipped. This creates a repeating pattern that flows across the surface. It’s a great choice when you want a consistent look without the prominent symmetry of a book match, making it feel more natural and less formal.

- Random match: Just like it sounds. The veneer leaves are placed randomly, intentionally mismatching grain and color. This embraces the natural wood variation to its fullest. It’s a bold choice that can deliver a rustic, plank-like effect or a highly modern, collage-style aesthetic.

Choosing your match: When to use each technique in a design

Knowing the techniques is good. Knowing when to deploy them is better.

- Use book match for statement pieces: Think conference tables, headboards, or the doors of a credenza. The symmetry draws the eye and signals high-end craftsmanship.

- Use slip match for large architectural surfaces: It’s the workhorse for wall panels, office interiors, and kitchen cabinetry. The continuous flow provides texture and warmth without overwhelming the space with a repeating mirror image.

- Use random match for character and texture: This is your go-to for accent walls in a hospitality setting, retail fixtures, or any piece where you want the material itself to be the art. It’s confident, honest, and full of energy.

Now, let's tie it all together and talk about how to use these variations to achieve your design vision.

From variation to vision: Using veneer intentionally

Understanding the cuts and matches is the technical part. The creative part is using that knowledge to tell a story with your design. Wood veneer isn’t just a surface covering; it’s an active design element. When you learn to control its direction, pattern, and texture, you move from just specifying a material to truly designing with it.

How can designers use wood veneer variations effectively?

- Guide the eye: The direction of the grain is a powerful tool. A strong vertical grain on wall panels can make a room with low ceilings feel taller. A horizontal grain on cabinetry can make a narrow space feel wider. Use the lines of the veneer to lead the viewer’s eye to a focal point.

- Create visual rhythm and texture: Don't be afraid to contrast patterns. Pair a bold, book-matched Burl Walnut panel with quieter, rift-cut Oak surfaces. This contrast creates visual depth and makes the statement piece even more impactful. Think of it like music, you need loud and quiet moments.

- Embrace the unexpected: Sometimes the most interesting part of a veneer sheet is the imperfection, a small knot, a mineral streak, a sudden shift in color. Instead of cutting around it, feature it. Centering a unique characteristic on a drawer front can turn a simple piece of furniture into a conversation starter.

Making the case for character: Talking to clients and stakeholders

This is often the final hurdle. You see character; your client sees a flaw. You see authenticity; they see inconsistency. It's your job to reframe the conversation.

- Shift the language. Stop saying uniform and start saying authentic. It’s not an inconsistency; it’s a unique characteristic. You’re not trying to hide variations; you’re celebrating the material’s story.

- Frame it as a mark of quality. In the world of luxury goods, uniqueness is value. A handmade leather bag is prized for its subtle variations. A solid wood table is defined by its grain. Position natural veneer in the same way as a premium, one-of-a-kind material that can't be replicated with a laminate.

- Show, don't just tell. Create renderings that celebrate the veneer. Point to high-end architectural projects that use natural materials with confidence. You’re not just choosing a finish; you’re making a statement that you value authenticity over sterile perfection. You're choosing to make something real.

Your new superpower: Designing with authenticity

So, the next time you unroll a sheet of veneer, you won’t just see a random pattern. You’ll see the end of a story, a record of dry seasons, windy hills, and rich soil, all captured in wood. And your job is to start its next chapter.

This knowledge is more than just trivia for a spec sheet. It's a fundamental shift. You’ve officially moved beyond just picking a finish from a catalog and into directing it. You now have the vocabulary to call for a slip-matched quarter-cut oak for its quiet, architectural flow or a book-matched burl for a stunning, symmetrical centerpiece, and know exactly why you’re doing it.

Think of it as adding a new instrument to your design orchestra. You can compose with texture, rhythm, and character in a way that sterile, mass-produced materials simply can’t replicate. This is how you create products with depth, and it’s the most powerful argument you have when making the case for authentic materials.

You’ve got the playbook. Now go design something with a story to tell.

Max Calder

Max Calder is a creative technologist at Texturly. He specializes in material workflows, lighting, and rendering, but what drives him is enhancing creative workflows using technology. Whether he's writing about shader logic or exploring the art behind great textures, Max brings a thoughtful, hands-on perspective shaped by years in the industry. His favorite kind of learning? Collaborative, curious, and always rooted in real-world projects.

Latest Blogs

How Fabric Texture Shapes Design Strategy in Fashion and Interior...

Fabric textures

3D textures

Mira Kapoor

Dec 10, 2025

DIY Textile Texture Techniques That Make Digital Designs Come Ali...

Fabric textures

Texture creation

Max Calder

Dec 8, 2025

Cost vs. Quality: A Decision Framework for PBR Textures

PBR textures

3D textures

Mira Kapoor

Dec 5, 2025