Finish to Function: The Future Trends in Plastic Material Texture

By Mira Kapoor | 17 September 2025 | 15 mins read

Table of contents

Table of Contents

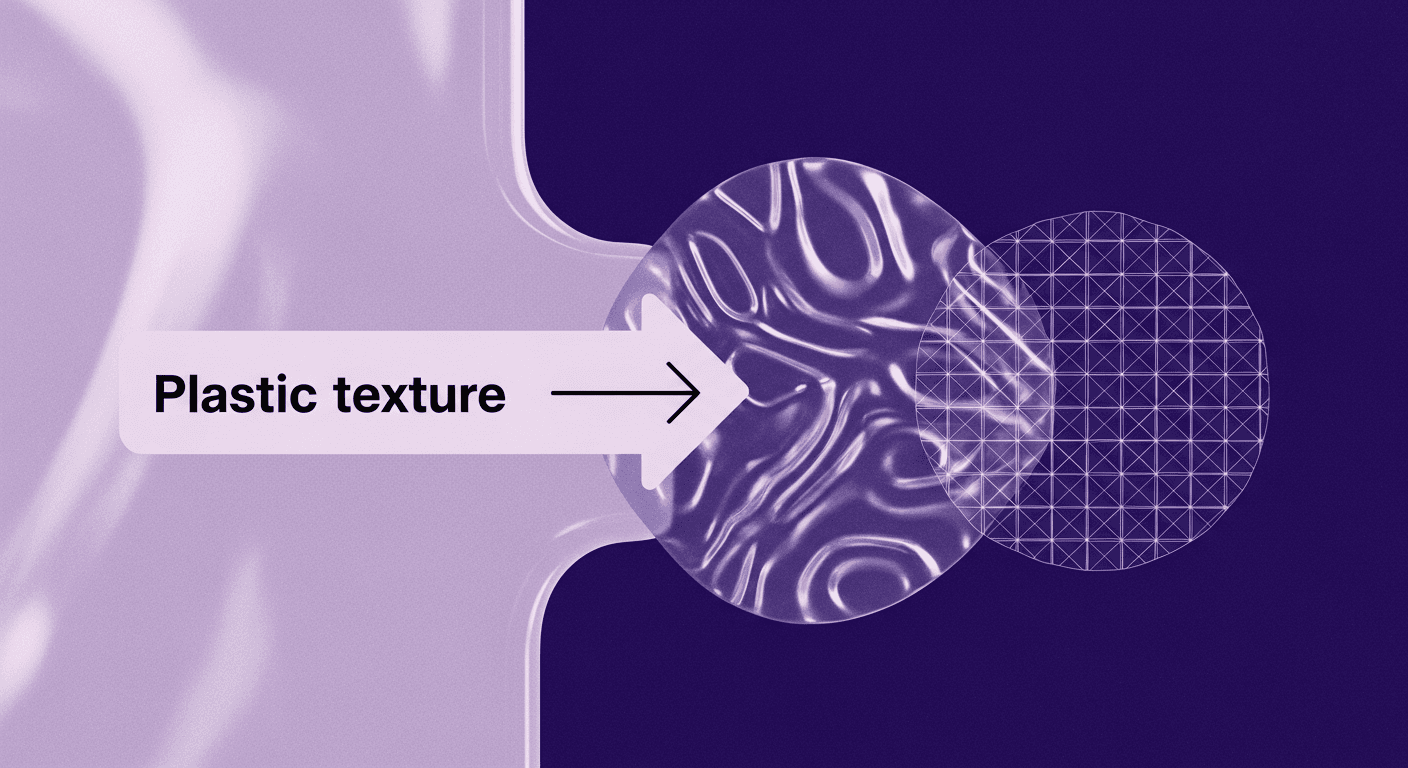

Plastic material textures are stepping out of the shadows and taking center stage in product design. They’re no longer just decorative layers; they influence how products look, feel, perform, and connect with users. As industries push for lighter materials, faster prototyping, and sustainable manufacturing, traditional mold-book approaches can’t keep up.

This guide explores the next wave of texture innovation from 5-axis laser ablation and nano-imprinting to smart surfaces that merge aesthetics with function. We’ll look at how these technologies are redefining the boundaries between digital design and physical manufacturing, enabling brands to create products that are visually striking, tactilely unique, and functionally smarter.

Why the future of plastic texture matters

In today’s hyper-competitive market, the surface of a product has become more than a finishing touch; it’s a storytelling tool, a differentiator, and often the first point of connection between brand and user. Plastic textures aren’t just about aesthetics anymore; they influence usability, perception, and even sustainability. As consumer expectations rise and digital design tools become more sophisticated, the industry is being pushed to rethink how textures are conceived, prototyped, and brought to life. The future belongs to workflows where creativity isn’t constrained by outdated processes but amplified by technology.

Beyond the basic mold: The limits of traditional texturing in modern industrial design

For decades, the playbook for plastic texturing has been pretty straightforward. You pick a pattern from a book, likely from a legacy supplier like Mold-Tech, and the toolmaker uses a chemical etching process to apply it to the mold. It’s a reliable system, but it’s a system built for a different era. Today, that process feels less like a tool for creativity and more like a set of constraints.

Most design teams are tired of flipping through the same catalogs of leather grains and geometric stipples. These textures are standardized, not strategic. They were designed for mass production, not for creating a unique brand identity or a truly memorable tactile experience. This approach forces you to design around a limited set of options rather than creating the exact finish your product deserves. The result? Products that feel generic, failing to stand out in a saturated market. The traditional method is slow, expensive to iterate, and fundamentally disconnected from the digital tools where your vision begins.

The disconnect between digital vision and physical prototype

Here’s a scenario every design manager knows too well: your team spends weeks perfecting a product in Keyshot or V-Ray. The lighting is perfect, the CMF is dialed in, and the texture on that main housing looks absolutely stunning on a 4K display. The stakeholders love it. They sign off. You send the files to the engineers, who translate your intent for the toolmaker.

Then, six weeks later, the first physical prototype arrives. And it’s… fine. But it’s not right. The texture that looked sharp and sophisticated in the render feels shallow and cheap in your hand. The subtle matte finish reflects light in a way you never anticipated. That critical gap between the digital vision and the physical part is where projects stall and budgets swell. It forces extra rounds of prototyping, creates friction between design and engineering, and delays time-to-market. This isn’t just an inconvenience; it’s a core business problem. The future of plastic material texture is about closing that gap for good.

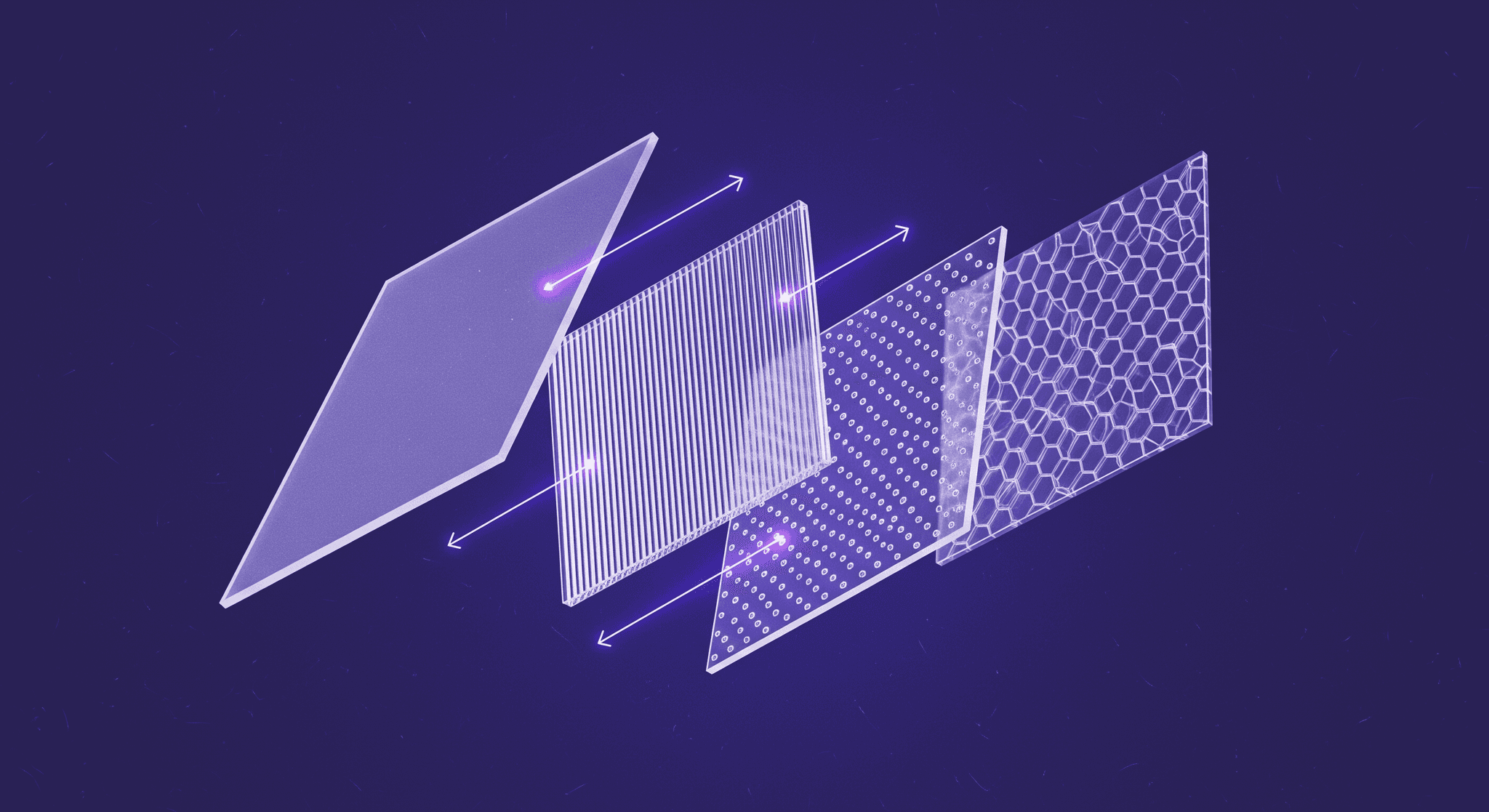

The engine room: Advanced plastic texture technologies you need to know

Closing the gap between screen and reality requires a new set of tools. The good news is, they’re here. These technologies aren’t just incremental improvements; they represent a fundamental shift in how we create and apply textures, moving from analog approximation to digital precision. This is the engine room driving next-generation plastic design.

Next-generation plastic design through digital and additive manufacturing

For years, prototyping a texture meant committing to an expensive and time-consuming tooling modification. Additive manufacturing changes that completely.

- How 3D printing is accelerating texture prototyping: Technologies like PolyJet and MultiJet Fusion allow you to print high-fidelity parts with integrated surface textures directly from your CAD files. Imagine designing three different grip textures for a power tool on Monday morning and holding all three physical versions in your hand by Wednesday afternoon. This lets you test ergonomics, feel, and aesthetics with real users, making data-driven decisions in days instead of months. It’s about failing faster and cheaper to get to the right solution.

- Direct digital texturing on molds: Once you’ve validated your texture, the goal is to replicate it perfectly in production. This is where direct laser texturing comes in. Instead of using acid to etch a pattern, a high-precision 5-axis laser directly ablates the surface of the steel mold. The laser works directly from your digital file, the same one you used for the prototype, to create patterns with a level of detail and complexity that chemical etching could never achieve. This creates a seamless digital thread from your design software straight to the final tool.

Polymer texture innovation in molding and finishing

Beyond just replicating digital files, new technologies are creating surfaces that were previously impossible to manufacture at scale.

- Laser ablation and etching for hyper-realistic surfaces: Because laser texturing is digitally controlled, it can create non-repeating, organic patterns that mimic natural materials with incredible fidelity. Think wood grains that don’t show a repeating pattern, or textiles that feel woven. It can also create micro-textures that refract light in unique ways, achieving finishes like brushed aluminum or satin chrome on a simple polymer part, eliminating the need for secondary painting or plating processes.

- Nano-imprinting for functional and optical effects: This is where material science advancements get really interesting. Nano-imprinting creates patterns on a surface that are so small, smaller than a wavelength of light, that they can fundamentally change the material’s properties. A nano-imprinted surface can be super-hydrophobic (water-repellent), create iridescent, color-shifting effects without any pigments, or even reduce friction. It’s a way to build functionality directly into the material’s surface at a microscopic level.

The rise of smart surfaces: Integrating function into form

This is the ultimate evolution: textures that aren't just seen or felt, but that do something. These surface engineering technologies are turning passive plastic shells into active interfaces.

- Haptic feedback textures: Imagine a button-less interface on a car dashboard. How do you know you’ve activated a control without looking? Smart surfaces can integrate haptic actuators that create localized vibrations, clicks, or pulses, providing tactile confirmation. The texture itself becomes part of the user interface.

- Self-healing and anti-microbial surfaces: Researchers are developing coatings and polymer additives that can make surfaces heal minor scratches when exposed to heat or UV light. Others integrate materials like silver ions to create inherently anti-microbial surfaces, a game-changer for medical devices, high-traffic interiors, and consumer electronics.

These technologies are the building blocks for the next wave of product design, where the surface of a product is as intelligent and functional as the electronics inside it.

More than looks: How innovative material surface engineering drives performance

Advanced textures are more than just a pretty face. They are a powerful tool for enhancing product performance, improving user experience, and even meeting sustainability goals. When you move beyond the default mold book, you unlock a new layer of design intent, transforming how a product feels, functions, and lasts.

Enhancing the user experience with functional textures

A product’s texture is one of the first things a customer notices; it communicates quality, purpose, and usability before they even turn it on.

- Improving grip, ergonomics, and tactile feedback: This is the most obvious function, but modern approaches go deeper. Instead of a generic diamond knurl, you can now design a multi-zone grip on a camera body, with a softer, more compliant texture where the palm rests and a sharper, more defined pattern for the fingertips. This level of ergonomic tuning, validated through rapid prototyping, creates a product that feels like a natural extension of the user's hand.

- Using texture to reduce visible wear and scratches: One of the biggest challenges with high-gloss plastic parts is that they look great on day one and are worn out after a month of use. Thoughtfully designed micro-textures can solve this. A subtle, matte pattern diffuses light, making fingerprints, smudges, and minor scratches virtually invisible. This extends the product's aesthetic lifespan and keeps it looking premium for longer, directly impacting customer satisfaction and brand perception.

Sustainability in texture design

How a product is finished has significant environmental implications. Innovative material surface engineering offers a cleaner path forward.

- How textures can reduce the need for paints and coatings: Secondary finishing processes like painting, plating, or applying soft-touch coatings often involve solvents and VOCs (Volatile Organic Compounds). They also add cost, time, and another potential point of failure in manufacturing. By using advanced laser texturing to achieve a desired look, like a brushed metal, a satin finish, or even a specific color through light refraction directly in the mold, you create a mono-material part. No paint, no coatings, just pure polymer.

- Designing for better recyclability and material efficiency: A mono-material part is far easier to recycle than a painted or coated one. When a product reaches the end of its life, there are no secondary layers to separate or strip. This streamlined approach not only reduces environmental impact but also simplifies the supply chain. You’re not just designing a product; you’re designing its entire lifecycle.

How are advanced textures transforming industrial design?

These capabilities are fundamentally changing the way designers work and what they can create, answering the key question of how advanced textures are transforming industrial design?

- Achieving new levels of photorealism: For too long, designers have had to accept a compromise between their digital renders and the final product. With a direct digital thread from a 3D material scan to a laser-textured mold, that compromise is disappearing. The texture you create and apply in your design software is the exact texture that will appear on the production line. This level of fidelity allows for bolder creative choices and ensures that stakeholder buy-in is based on a true representation of the final product.

- Creating multi-sensory product experiences: Texture is a key component in a product's sensory footprint. It works alongside form, color, and sound to tell a story. An electric vehicle interior can use textures to feel both futuristic and calming. A piece of audio equipment can use precision-etched patterns to communicate accuracy and high fidelity. By mastering texture, you move beyond purely visual design and start crafting holistic, memorable experiences that build a stronger emotional connection with the user.

The future in practice: Cross-industry applications of advanced textures

Theory is great, but seeing these technologies in action is where the potential really clicks. The future trends in plastic material texture are already taking shape across multiple industries, solving real-world problems and creating new opportunities for innovation.

Case Study: Automotive interiors get smarter and more sustainable

Automotive interiors are a perfect showcase for advanced textures. Designers are tasked with creating a premium, durable, and functional environment while also meeting aggressive weight and sustainability targets. Instead of using genuine wood or metal trim, which is heavy, expensive, and often has a high carbon footprint, manufacturers are using laser ablation to create hyper-realistic patterns on polymer panels. These textures perfectly mimic the look and feel of natural materials but are lighter, more durable, and fully recyclable. Furthermore, we're seeing the rise of "hidden-til-lit" surfaces. A seamless, textured panel on the dashboard might look like decorative trim, but when the car is on, light shines through micro-perforations to reveal controls, creating a clean, minimalist interface that only appears when needed.

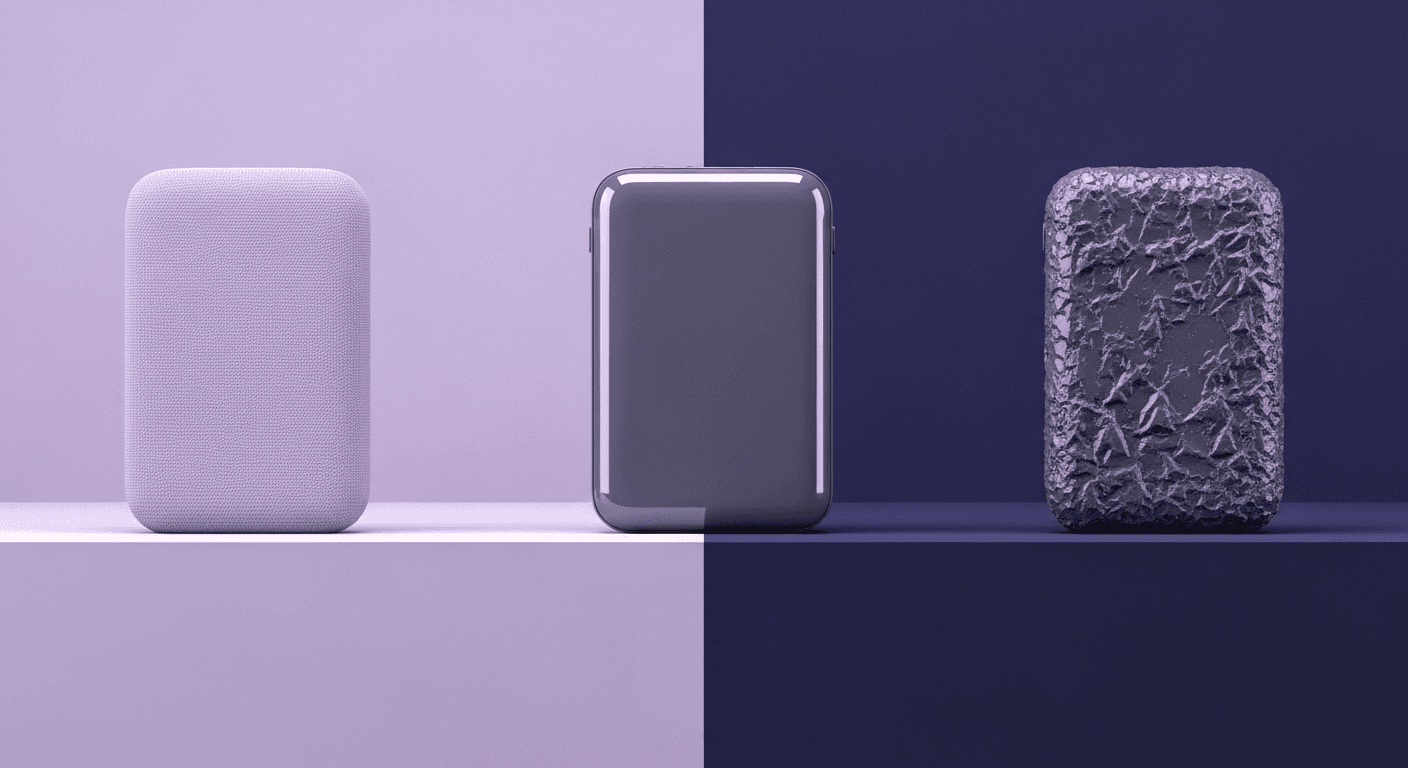

Case Study: Consumer electronics that feel as good as they perform

In the world of consumer electronics, the tactile experience is a core part of the brand. Think about the finely textured aluminum on a MacBook or the soft-touch finish on a high-end gaming mouse. Manufacturers are now achieving these premium finishes without the premium materials. Using advanced molding and texturing, a simple polycarbonate or ABS housing can be given a surface that feels like anodized metal, soft Alcantara fabric, or even ceramic. This isn't just about mimicry; it's about performance. Textures are engineered to resist fingerprints, improve grip during long gaming sessions, and dissipate heat more effectively. The result is a device that feels meticulously crafted and thoughtfully designed, reinforcing its value and performance.

Case Study: Medical devices where texture improves safety and usability

Nowhere is functional texture more critical than in the medical field. For surgical instruments, an ergonomic grip isn't a luxury; it's a necessity for precision and control. Designers are using 3D-printed prototypes to test and refine grip patterns that remain effective even when wearing surgical gloves. The final production tools are then laser-textured to replicate these patterns with perfect accuracy. Beyond ergonomics, anti-microbial textures are being molded directly into the surfaces of high-touch devices like monitoring equipment and hospital bed controls. By integrating silver ions or creating nano-textures that inhibit bacterial growth, these surfaces enhance patient safety and reduce the reliance on harsh chemical cleaners. Here, texture isn't an aesthetic choice; it’s a critical component of the product's function and safety profile.

Your next move: Integrating these trends into your design workflow

Understanding these trends is the first step. The next step is to build them into your team’s process. This isn’t about throwing out your current workflow, but about upgrading it with new tools and a new mindset to make the business case for the future of surface engineering in plastic materials.

Tools and techniques to streamline communication between design and engineering

The classic point of failure is the handoff from design to engineering. The fix is to create a single source of truth, a digital one. Instead of relying on physical reference swatches and ambiguous notes like "a light satin finish," your workflow should center on digital material files.

- Embrace digital material libraries: Tools like Texturly and scanners from companies like Vizoo allow you to create or capture photorealistic, tileable textures. These aren't just images; they're data-rich files containing information about color, roughness, and normal maps. This digital material becomes the master reference.

- Share the source file: This master file can be used in your rendering software for stakeholder presentations, and the exact same file can be sent to a mold maker who uses 5-axis laser texturing. This eliminates interpretation and ensures what you see on screen is what you get in the mold. The digital file is the spec.

A practical guide to specifying and sourcing next-generation textures

When you engage with manufacturing partners, you need to ask the right questions to see if they’re ready for this new workflow.

- Start the conversation early: Bring your manufacturing partner into the design process sooner. Show them the digital materials you're working with and ask about their capabilities.

- Key questions for vendors:

- "Do you have 5-axis laser texturing capabilities, or do you rely solely on chemical etching?"

- "Can you work directly from our digital material files (e.g., TIFF, STP)?"

- "Can you produce textured sample plaques for us to validate CMF intent before cutting the main tool?"

A partner who answers "yes" to these questions is equipped for a modern, digital workflow. Those who can’t are likely still stuck in the old, analog process.

How to make the business case for investing in the future of surface engineering in plastic materials

As a manager, you need to justify this investment not as a creative indulgence, but as a strategic business decision. Frame the conversation around these three key pillars:

- Speed and cost reduction: By validating textures with fast, inexpensive 3D prints, you dramatically reduce the risk of costly changes to production tooling. Fewer tool modifications mean a faster time-to-market. You’re not just saving money on tooling; you’re getting to revenue sooner.

- Increased product value and differentiation: A unique, thoughtfully designed texture can elevate a product, allowing it to command a higher price point and stand out from competitors. It’s a tangible differentiator that customers can see and feel. This isn't a cost; it's an investment in brand equity.

- Meeting corporate sustainability goals: Eliminating secondary processes like painting and plating doesn't just simplify manufacturing, it reduces your product's environmental footprint. Molded-in textures help your company meet its ESG (Environmental, Social, and Governance) targets, which is increasingly important to investors and consumers alike.

Where we go from here

For years, the texture of a product was something you chose. You picked it from a book, handed it off, and hoped for the best. That era is over.

The real shift isn't just about lasers or 3D printers, it's about control. It's about closing that expensive gap between the digital render and the physical part for good. It means you’re no longer just designing the shape of a product; you’re authoring its entire tactile identity, directly from your desktop.

This is how you turn that six-week prototype wait from a moment of anxiety into a formality. It’s about building a seamless digital pipeline where what you see in Keyshot is exactly what comes out of the production tool. It’s about giving your team the ability to test, iterate, and validate a feeling in hours, not months.

The tools are here. The workflow is clear. The only question left is what you will create now that your vision isn't limited to the pages in a binder?

Mira Kapoor

Mira leads marketing at Texturly, combining creative intuition with data-savvy strategy. With a background in design and a decade of experience shaping stories for creative tech brands, Mira brings the perfect blend of strategy and soul to every campaign. She believes great marketing isn’t about selling—it’s about sparking curiosity and building community.

Latest Blogs

How 4K Seamless Textures Transform Flat CG Into Tangible Fabric

PBR textures

Fabric textures

Max Calder

Nov 21, 2025

Beyond Color and Gloss: How Plastic Texture Tells Your Product's ...

Product rendering

Texture creation

Max Calder

Nov 19, 2025

Decode Plastic Material Texture: The Team Language That Prevents ...

Product rendering

Texture creation

Mira Kapoor

Nov 17, 2025